Plastic Formwork Market Outlook:

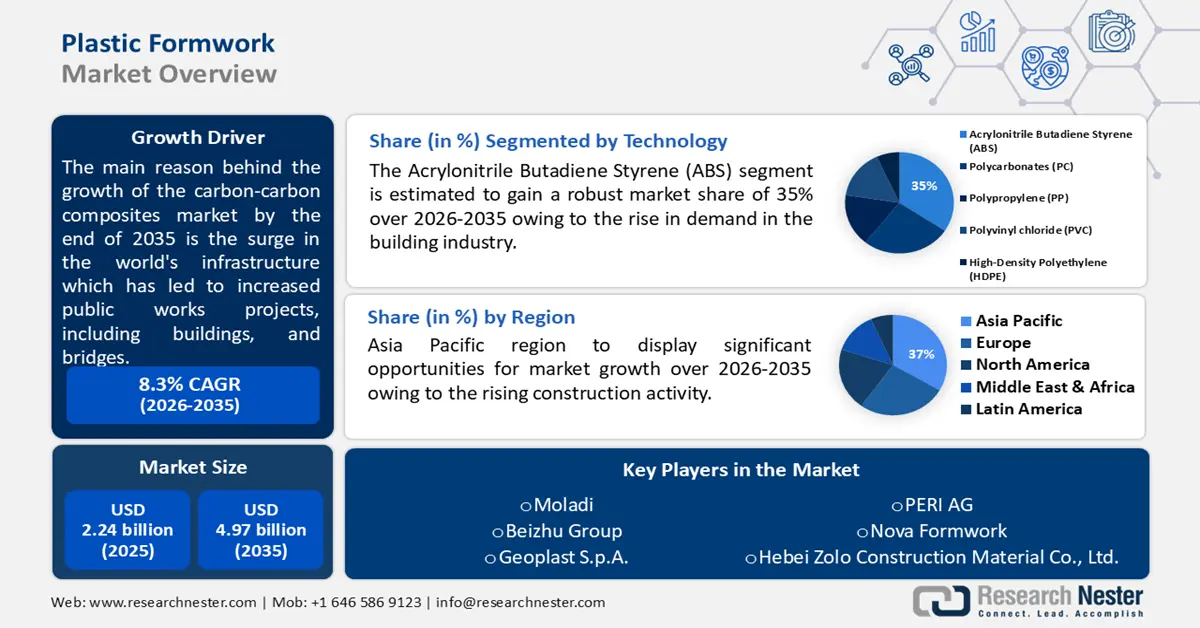

Plastic Formwork Market size was over USD 2.24 billion in 2025 and is projected to reach USD 4.97 billion by 2035, witnessing around 8.3% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of plastic formwork is evaluated at USD 2.41 billion.

The plastic formwork market is expanding due to the surge in the world's infrastructure which has led to increased public works projects, including building, bridge, and road construction. According to the World Bank, the number of people worldwide will increase by about 2 billion by 2040, a 25% increase. With the urban population expected to rise by 46%, there will be a continued migration from rural to urban areas, creating a huge need for infrastructure assistance.

This can result in a larger demand for economical and efficient building techniques, such as plastic formwork systems. Systems for plastic formwork are made to be simple to carry, assemble, and disassemble. This might lead to shorter construction schedules, enabling projects to be finished sooner. Because infrastructure projects want to minimize disruptions and downtime, the efficiency of plastic formwork may be a selling point.

Key Plastic Formwork Market Insights Summary:

Regional Highlights:

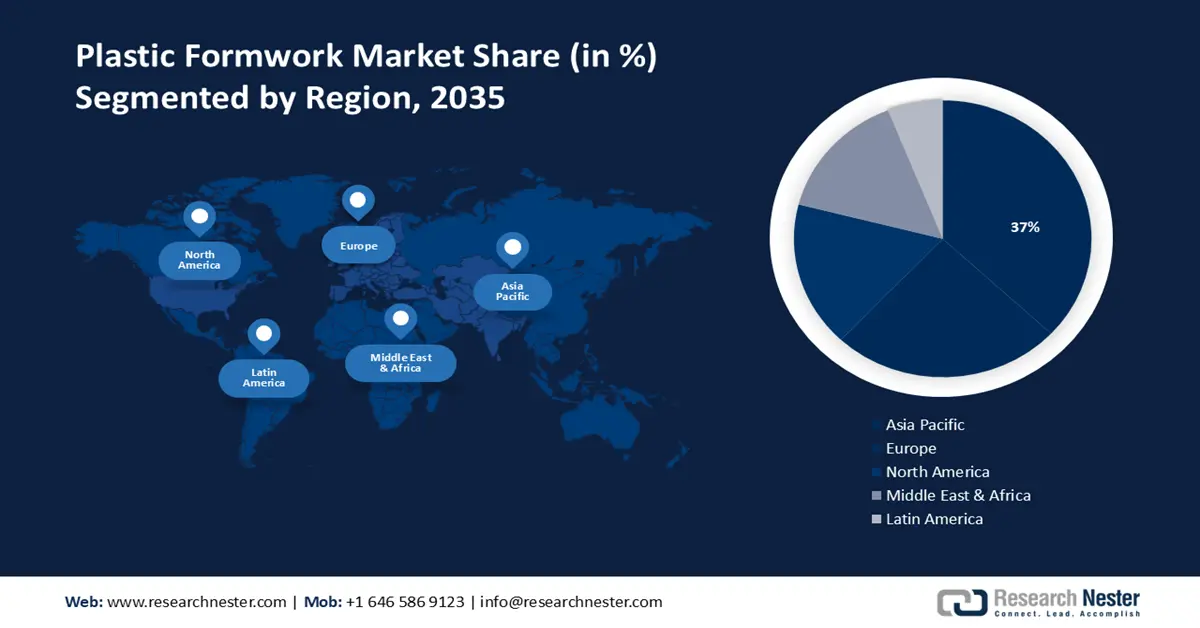

- Asia Pacific plastic formwork market is anticipated to capture 37% share by 2035, driven by rising construction activity, urbanization, and government programs.

Segment Insights:

- The modular formwork segment in the plastic formwork market is anticipated to secure a 38% share by 2035, driven by its cost-effective, reusable, and efficient prefabricated panel systems.

- The acrylonitrile butadiene styrene (abs) segment in the plastic formwork market is expected to gain substantial share by 2035, driven by high demand due to its strength and sustainability.

Key Growth Trends:

- Surge in the global trend for sustainable construction

- Benefits offered by plastics formwork

Major Challenges:

- Restriction of materials and rigidity of structure

- Lack of Awareness

Key Players: Moladi, Beizhu Group, Geoplast S.p.A., PERI AG, Nova Formworks, Hebei Zolo Construction Material Co., Ltd., Shandong Green Plastic Co., Ltd., NOE Formwork, ULMA Group, Acrow.

Global Plastic Formwork Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 2.24 billion

- 2026 Market Size: USD 2.41 billion

- Projected Market Size: USD 4.97 billion by 2035

- Growth Forecasts: 8.3% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (37% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: China, United States, Germany, Japan, India

- Emerging Countries: China, India, Thailand, Indonesia, Brazil

Last updated on : 17 September, 2025

Plastic Formwork Market Growth Drivers and Challenges:

Growth Drivers

- Surge in the global trend for sustainable construction - The building industry has started a shift toward environmentally conscious methods as communities and companies become more aware of the pressing need for the road of transformation. According to the International Finance Corporation (IFC), access to climate-friendly financing markets that direct greater investment to the construction value chain and energy-efficient design, construction, and operations techniques could reduce emissions by 12.8% from 2022 levels by 2035.

In this setting, plastic formwork shows up as a key change agent. Its success is a result of its radical break from traditional building techniques, which frequently call for the use of resources-intensive materials like steel and wood. In addition to reducing the negative environmental impact, the industry gains access to a wealth of benefits by using plastic, a lightweight and reusable substitute. Plastic formwork's inherent lifespan and recyclability contribute to its eco-friendliness. - Benefits offered by plastics formwork - Because plastic formwork makes assembly and disassembly simpler, it expedites the construction process. Quick assembly and disassembly are made possible by the lightweight, modular design, which lowers labor costs and speeds up project completion.

Contractors and developers trying to maximize building timetables and reduce labor costs will be drawn to this greater efficiency. Because plastic formwork has so many benefits over traditional formwork methods, the plastic formwork market for it is expanding. Lightweight components that are simple to construct, disassemble, and transport are provided by this creative approach. - Growing demand in residential construction - The residential construction industry is driven by the expanding urban population and the growing need for affordable homes. Furthermore, plastic formwork presents a feasible option for residential projects due to its ability to reduce costs, expedite construction, and enhance quality. Additionally, the plastic formwork market may find chances in remodeling projects due to the increasing requirement for older structures to be renovated and retrofitted.

Challenges

- Restriction of materials and rigidity of structure - The plastic formwork market is severely constrained by the inability to handle materials well enough to support large loads and intricate structural layouts. While plastic formwork is appropriate for many different types of building projects, it can be problematic when applied to intricate architectural designs or substantial concrete loads. Plastic formwork has its limitations and conventional formwork systems may offer greater structural rigidity and longevity in some situations.

- Lack of Awareness - Plastic formwork is still relatively new in the building business, despite its advantages. Its widespread adoption may be hampered by contractors' and builders' lack of knowledge and experience. Therefore, this factor may hinder the growth of the plastic formwork market.

Plastic Formwork Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

8.3% |

|

Base Year Market Size (2025) |

USD 2.24 billion |

|

Forecast Year Market Size (2035) |

USD 4.97 billion |

|

Regional Scope |

|

Plastic Formwork Market Segmentation:

Material Type Segment Analysis

Acrylonitrile butadiene styrene (ABS) segment is poised to account for substantial plastic formwork market share by 2035. The ABS segment is predicted to be led by the rise in demand in the building industry. Because of its extraordinary qualities, ABS is today a highly sought-after material for use in construction, demonstrating its crucial influence on the development of contemporary building techniques. The exceptional combination of qualities that ABS possesses to meet the needs of construction environments accounts for its ongoing appeal.

ABS is exceptionally strong and resilient, demonstrating a strong resistance to impact and being able to survive the demanding conditions of construction work. By reducing waste and maximizing resource use, this resilience extends to its potential for numerous applications, which helps to achieve the main objective of sustainability in the construction industry. For instance, it is anticipated that green buildings will cut CO2 emissions by 34%.

Type Segment Analysis

Modular formwork segment is projected to dominate over 38% plastic formwork market share by 2035. One significant building method that has revolutionized the construction of concrete structures is modular formwork. Modular formwork is a popular option in the building industry because of its prefabricated panels and components, which provide variety, efficiency, and cost-effectiveness from project to project. This cutting-edge technology has numerous uses in a range of construction projects, such as residential and commercial complexes, industrial structures, bridges, and buildings.

Systems of modular formwork are made to be readily put together, changed, and taken apart. Furthermore, modular formwork solutions provide cost reductions in several ways. For instance, because modular formwork components can be disassembled and reused for other project sections or future endeavors, their reusability reduces material waste.

Our in-depth analysis of the global plastic formwork market includes the following segments:

|

Type |

|

|

Material Type |

|

|

Application |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Plastic Formwork Market Regional Analysis:

APAC Market Insights

Asia Pacific industry is poised to hold largest revenue share of 37% by 2035. The market growth in the region is also expected on account of rising construction activity, fast urbanization, and government programs to support affordable housing and sustainable construction practices. There could be an additional 2.5 billion people living in urban areas by 2050 as a result of urbanization—the gradual movement of people from rural to urban areas—and global population growth. Nearly 90% of this increase is expected to occur in Asia, according to a new United Nations’ data set. Also, increase in demand for green buildings is contributing to the growth of the plastic formwork market in the region.

China's market for plastic formwork is expanding as a result of rising expenditures for infrastructure construction. The Chinese government is concentrating on building more roads, bridges, and tunnels as part of its transportation network expansion, which calls for effective and affordable formwork solutions. According to a report, fixed-asset investment in China's transportation sector exceeded 18 trillion yuan between 2019 and 2023.

Korean construction firms, with their aggressively acquired competitive advantages, will continue to extend into further international markets, participating in major reconstruction and infrastructure projects and likely becoming a global force, which is influencing the growth of plastic formwork in the region. According to the data privacy framework, services rendered abroad accounted for almost 13% of the overall income earned by Korean construction companies in 2019. Korea is still very focused on growing its earnings from ventures abroad.

European Market Insights

The Europe region will also observe lucrative growth for the plastic formwork market during the forecast period and will hold the second position owing to the growing popularity of innovative materials like plastic formwork. In addition to this, the strict environmental rules are another factor impacting the growth of the plastic formwork market in the region.

According to the European Environmental Bureau, beginning at the end of 2026, the EU will finally develop green public procurement (GPP) regulations for building materials. If these proposed regulations are successful in resolving the current fragmentation of GPP systems across Member States, they may guarantee green products with public spending on construction activities, which accounts for 14% of the EU's GDP.

The growing demand for retrofitting existing structures will drive the growth of the plastic formwork market in the UK. According to the UK Green Building Council, the UK's Retrofit for the Future initiative served as the impetus for the retrofit of more than 100 homes, with the goal of reducing each property's in-use CO2 emissions by 80%.

Plastic Formwork Market Players:

- Moladi

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Beizhu Group

- Geoplast S.p.A.

- PERI AG

- Nova Formworks

- Hebei Zolo Construction Material Co., Ltd.

- Shandong Green Plastic Co., Ltd.

- NOE Formwork

- ULMA Group

- Acrow

The majority of the market share in the highly consolidated worldwide plastic formwork market is held by a limited number of large-scale vendors. The majority of businesses are making large investments in thorough research and development projects, mostly with the goal of producing environmentally friendly goods. Leading players have embraced mergers and acquisitions and product portfolio expansion as their primary business strategies.

Recent Developments

- Moladi, a leader in the world of reusable plastic formwork for use in low-cost and affordable housing projects, primarily in developing nations, and iLima Digital Foundry will introduce new construction technologies and business models for affordable housing in South Africa. The Smart Building Advisor (SBA) and Africa Construction Innovation Platform (ACIP) from iLima will support South African construction companies and advance the development of ACIP expertise throughout Africa.

- Geoplast S.p.A. introduced Skynet, the only lightweight fill formwork that fully conforms with the international building regulations Eurocode (EC2), NTC2018, and ACI213. Skynet provides complete structural reliability, as opposed to unstable and unsustainable alternatives such as compacted earth and gravel. This is due to its massive, 71×71 cm top formwork, which forms ribbed concrete slabs that are 25-35 cm tall, and its Ø250-300 mm tubes, which create high load-bearing columns that meet with international norms.

- Report ID: 6179

- Published Date: Sep 17, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Plastic Formwork Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.