Waterjet Cutting Machine Market Outlook:

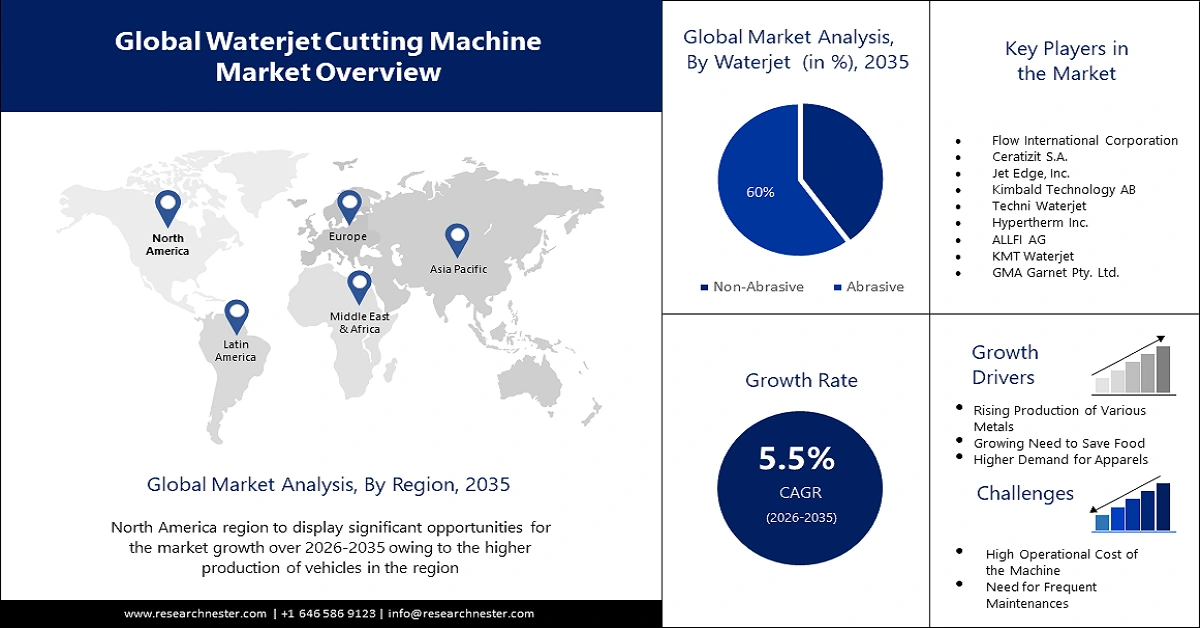

Waterjet Cutting Machine Market size was valued at USD 1.46 billion in 2025 and is set to exceed USD 2.49 billion by 2035, registering over 5.5% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of waterjet cutting machine is evaluated at USD 1.53 billion.

The market growth is driven by growing production of metals. Waterjet is typically used in cutting a wide range of metals and making products out of them, therefore higher production of metals will increase the usage of waterjet. The globe mined around 181 million tonnes of different metals in 2021, including aluminum, chromium, copper, magnesium, zinc, lead, titanium, nickel, zinc, and others. Furthermore, growing production of new clothes will boost the market revenue. Every year, around 80 billion to 100 billion new clothes are produced in the world. Waterjet cutting machines can handle multiple layers of fabric simultaneously, allowing for efficient mass production of clothes.

Key Waterjet Cutting Machine Market Insights Summary:

Regional Highlights:

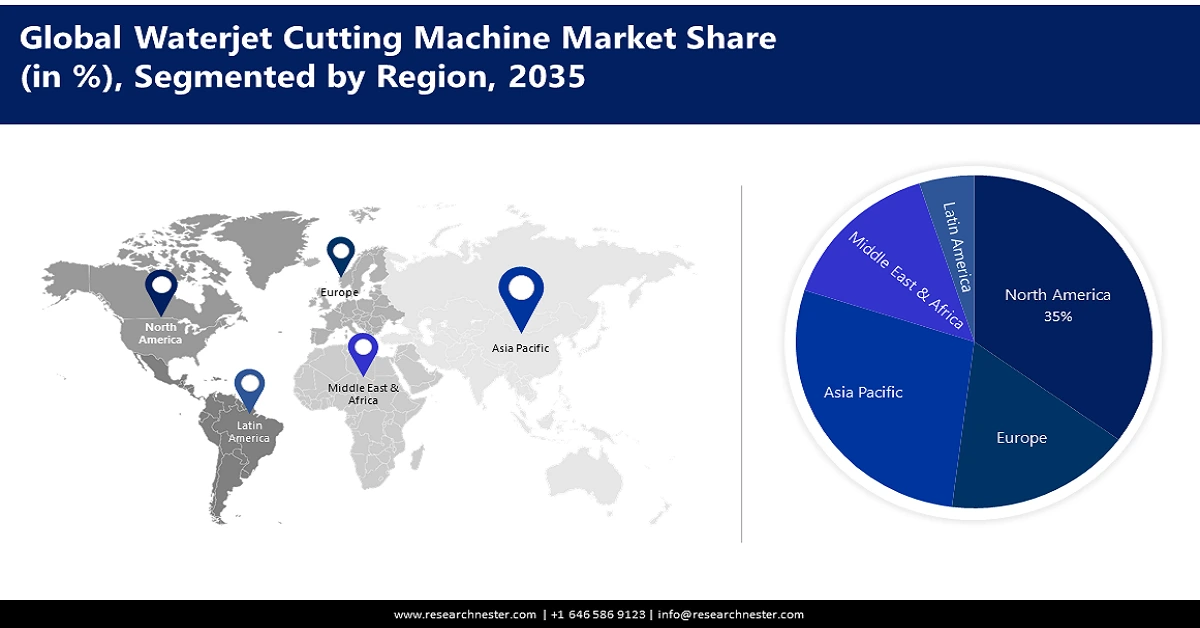

- North America waterjet cutting machine market is poised to capture 35% share by 2035, driven by increasing production of automobiles and the presence of a large network of SMEs in Canada.

- Asia Pacific market will secure 28% share by 2035, driven by rising manufacturing industry, with China and India advancing rapidly.

Segment Insights:

- The abrasive segment in the waterjet cutting machine market will hold a 60% share, driven by high accuracy and precision in material cutting, 2026-2035.

- The automotive segment in the waterjet cutting machine market is expected to hold a 38% share by 2035, driven by waterjet’s suitability for cutting a variety of automotive materials with precision.

Key Growth Trends:

- Rising Need to Reduce Food Wastage

- Rise in the Number of Wind Energy Projects

Major Challenges:

- High Operational Costs

- Instances of Downtime

Key Players: Kennametal Inc., Flow International Corporation, Ceratizit S.A., Jet Edge, Inc., Kimbald Technology AB, Techni Waterjet, Hypertherm Inc., ALLFI AG, KMT Waterjet, GMA Garnet Pty. Ltd., OMAX Corporation.

Global Waterjet Cutting Machine Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 1.46 billion

- 2026 Market Size: USD 1.53 billion

- Projected Market Size: USD 2.49 billion by 2035

- Growth Forecasts: 5.5% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: North America (35% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: United States, China, Japan, Germany, South Korea

- Emerging Countries: China, India, Japan, South Korea, Thailand

Last updated on : 8 September, 2025

Waterjet Cutting Machine Market Growth Drivers and Challenges:

Growth Drivers

- Rising Need to Reduce Food Wastage– Globally, around 1.3 billion of food is wasted every year, which accounts for one-third of the total produce. Owing to higher food wastage the need for waterjet cutting becomes important since it allows for precise cuts and portioning thus preventing the wastage of food.

- Rise in the Number of Wind Energy Projects– In 2021, global offshore wind installations reached a new high of 17,398 MW, bringing the total capacity currently operational to 50,623 MW. A waterjet cutting machine is used for the manufacturing of wind turbines, which are made up of carbon fiber tape or fiberglass.

- Rising Investment in Defense Sector- In 2021, total worldwide military spending grew by 0.7% in real terms to USD 2113 billion. Higher investment leads to the production of better defense equipment, waterjet is used in prototyping the equipment and makes necessary personalization.

Challenges

- High Operational Costs- On the top of upfront cost of the waterjet cutting machine, the operation cost of the equipment is also very high. The operational costs include consumables such as maintenance, and energy consumption. Moreover, the operational cost is an ongoing cost and adds up over time.

- Instances of Downtime

- Hard to achieve accuracy

Waterjet Cutting Machine Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

5.5% |

|

Base Year Market Size (2025) |

USD 1.46 billion |

|

Forecast Year Market Size (2035) |

USD 2.49 billion |

|

Regional Scope |

|

Waterjet Cutting Machine Market Segmentation:

Waterjet Segment Analysis

The abrasive segment is estimated to hold around 60% share of the global waterjet cutting machine market by 2035. The segment growth can be attributed to need for high accuracy while cutting the materials. In comparison to other types of waterjet and other technologies, such as plasma cutting and others, abrasive waterjet cutting machines offer a high level of precision, enabling the carving of complete and intricate designs.

End User Segment Analysis

The automotive segment is expected to garner a significant share of around 38% by 2035. Modern automobiles are built using a wide range of advanced materials, such as advanced plastic, metals, glass, and composites. Waterjet cutting machine is highly suitable for the automotive industry as it provides high precision with all these materials. The typical automobile contains 30,000 parts, nearly one-third of which are made of plastic, that includes, handles, dashboards, panels, seating, cable insulation, and others.

Our in-depth analysis of the global market includes the following segments:

|

Offering |

|

|

Product Type |

|

|

Waterjet |

|

|

End User |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Waterjet Cutting Machine Market Regional Analysis:

North American Market Insights

The waterjet cutting machine market in North America is poised to be the largest with a share of about 35% by the end of 2035. The market growth in the region can be attributed to increasing production of automobiles. The United States is one of the largest producers of automobiles, and the demand for waterjet cutting machines has increased dramatically. On the other hand, the presence of a large network of small and medium-sized businesses in Canada has boosted the manufacturing units of the region.

APAC Market Insights

The Asia Pacific waterjet cutting machine market is estimated to dominate a share of about 28% by 2035. The market growth is impelled by rising manufacturing industry. Asia Pacific has become the new hub for the manufacturing of products. Countries such as China have achieved a major mark in the manufacturing industry and India is also rapidly advancing. We anticipate that ASEAN manufacturing production might increase by USD 400 billion to USD 600 billion per year by 2030, compared to 2020 levels.

Waterjet Cutting Machine Market Players:

- Kennametal Inc.

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Flow International Corporation

- Ceratizit S.A.

- Jet Edge, Inc.

- Kimbald Technology AB

- Techni Waterjet

- Hypertherm Inc.

- ALLFI AG

- KMT Waterjet

- GMA Garnet Pty. Ltd.

- OMAX Corporation

Recent Developments

- June 2021: Ceratizit S.A. announced has acquired the rest shares of Ceratizit Log Angeles, also known as Carbide Cutting Tools. This will boost the strategy for producing advanced cutting tools.

- March 2023: Hypertherm Associates announced the launch of ProNest LT 2023 version 151 nesting software. It is a subscription-based platform for waterjet cutting.

- Report ID: 1531

- Published Date: Sep 08, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Waterjet Cutting Machine Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.