End Milling Machine Market Outlook:

End Milling Machine Market size was valued at USD 3.78 Billion in 2025 and is likely to cross USD 6.83 Billion by 2035, expanding at more than 6.1% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of end milling machine is assessed at USD 3.99 Billion.

As industries continue to expand, there is a growing demand for machinery like end milling machines to produce precision parts and components. An end milling machine is a type of milling machine that can be used to cut a variety of materials, such as metals, plastics, and composites. It is commonly used in industries such as automobile manufacturing, aerospace, and shipbuilding.

Continuous technological advancements in end milling machines such as Computer Aided Dispatch (CAD), CNC (Computer Numerical Control) have led to improved efficiency, accuracy, and automation. CNC systems have become more sophisticated, enabling complex machining tasks, which are increasingly in demand. CNC machines are able to quickly and accurately produce intricate parts with a high degree of precision. This has resulted in increased productivity and cost savings for manufacturers, allowing them to produce more parts in less time.

Key End Milling Machine Market Insights Summary:

Regional Highlights:

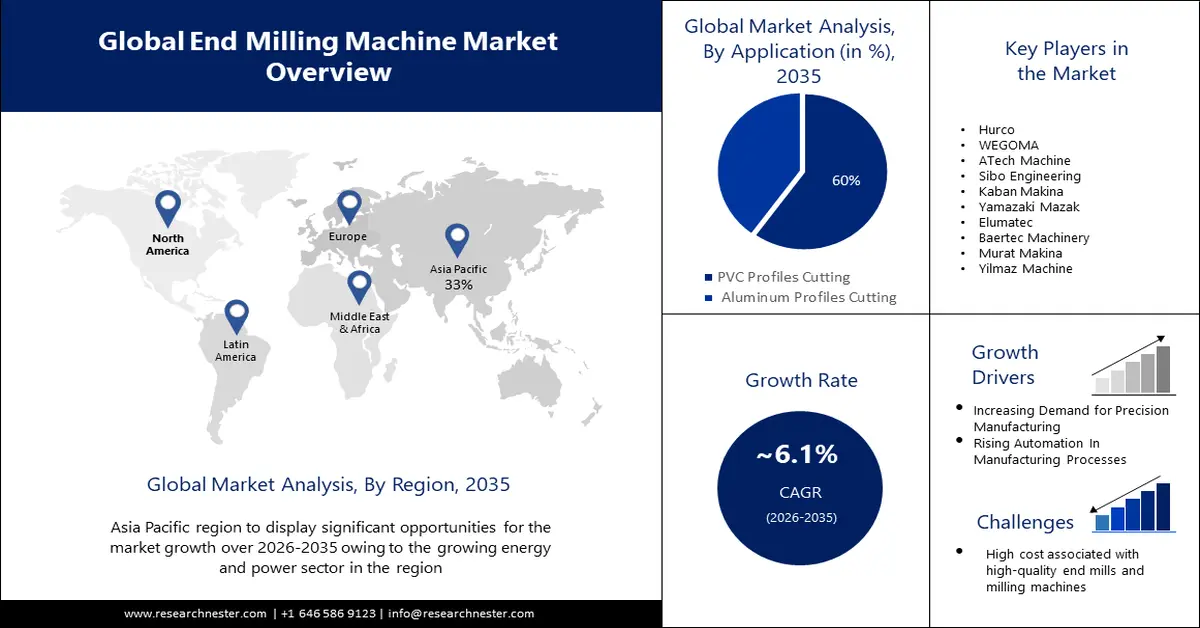

- Asia Pacific end milling machine market is projected to capture a 33% share by 2035, driven by the ever growing energy and power sector.

- North America market is expected to secure a 28% share by 2035, driven by the expansion of educational institutions and training centers in the region.

Segment Insights:

- The pvc profiles cutting segment in the end milling machine market is anticipated to achieve a 60% share by 2035, attributed to increasing use of PVC profiles for energy-efficient windows and doors.

- The variable-angle segment in the end milling machine market is projected to hold a 58% share by 2035, driven by rising demand for precision machining and complex component manufacturing.

Key Growth Trends:

- Increasing Demand for Precision Manufacturing

- Rising Automation In Manufacturing Processes

Major Challenges:

- Complexity Regarding Material Hardness

- High cost associated with high-quality end mills and milling machines

Key Players: WEGOMA, Hurco, ATech Machine, Sibo Engineering, Kaban Makina, Yamazaki Mazak, Elumatec, Baertec Machinery, Murat Makina, Yilmaz Machine.

Global End Milling Machine Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 3.78 Billion

- 2026 Market Size: USD 3.99 Billion

- Projected Market Size: USD 6.83 Billion by 2035

- Growth Forecasts: 6.1% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (33% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: United States, Germany, China, Japan, Italy

- Emerging Countries: China, India, Japan, South Korea, Taiwan

Last updated on : 11 September, 2025

End Milling Machine Market Growth Drivers and Challenges:

Growth Drivers

-

Increasing Demand for Precision Manufacturing- As manufacturers strive to produce complex parts with tighter tolerances, they require machines that can deliver high levels of accuracy and consistency. End Milling Machines are an essential tool for precision manufacturing, as they allow manufacturers to create complex shapes and contours with high levels of accuracy. By using advanced software and cutting tools, these machines can achieve tolerances as tight as 0.0005 inches, making them ideal for applications that require extreme precision. For instance, End Milling Machines are used to create turbine blades for jet engines, which require intricate geometries and tight tolerances to function properly.

-

Rising Automation In Manufacturing Processes- The increasing automation of manufacturing processes has been a major driving force behind the rising demand for End Milling Machines. As more and more factories move towards automation, the need for precision machinery like end milling machines becomes even more critical. In fact, according to industry reports, the industrial automation is expected to reach USD 300 billion by 2024. More than two thirds of manufacturing activities can be automated, making the manufacturing industry the most significantly affected by automation. A report suggests that implementing automation in 68% of manufacturing tasks could potentially save 740 billion working hours globally.

- Growing Demand for Customized Products- As consumers continue to place a premium on unique and personalized items, manufacturers are under pressure to deliver products that meet these demands. end milling machines play a critical role in this process, as they allow manufacturers to create precise cuts and shapes that are tailored to each individual product. In addition to meeting consumer demands, end milling machines also offer numerous benefits to manufacturers. By using these machines, manufacturers can reduce waste, improve efficiency, and increase productivity. This is particularly important in industries where time and precision are of the essence, such as aerospace and automotive manufacturing.

Challenges

-

Complexity Regarding Material Hardness: Milling hard materials like hardened steel or exotic alloys can accelerate tool wear and reduce cutting efficiency. Specialized tools and cutting strategies are often required for these materials.

-

Need for Regular maintenance to keep end milling machines in optimal working condition

- High cost associated with high-quality end mills and milling machines

End Milling Machine Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

6.1% |

|

Base Year Market Size (2025) |

USD 3.78 Billion |

|

Forecast Year Market Size (2035) |

USD 6.83 Billion |

|

Regional Scope |

|

End Milling Machine Market Segmentation:

Type Segment Analysis

The variable-angle segment is estimated to hold around 58% share of the global end milling machine market in the year 2035. The segment growth can be attributed to the increasing demand for milling tools and applications that require complex shapes. Also, the increasing demand for precision machining and the growing demand for complex components that require multi-axis machining are expected to drive the growth of this segment. Furthermore, technological advancements such as the development of multi-axis machining centers and the increasing adoption of automation are also expected to drive the growth of the variable-angle segment.

Application Segment Analysis

End milling machine market from the PVC profiles cutting segment is estimated to gain a significant share of about 60% in the year 2035. The segment growth can be attributed to the increasing use of PVC profiles in various applications, such as window and door frames, gutters, and roof flashings. PVC profiles are cheap and easy to install, making them a popular choice for window and door frames. Furthermore, the growing demand for energy-efficient doors and windows is expected to drive the growth of the PVC profiles cutting segment over the forecast period.

Our in-depth analysis of the global end milling machine market includes the following segments:

|

Type |

|

|

Application |

|

|

End Use |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

End Milling Machine Market Regional Analysis:

APAC Market Insights

Asia Pacific industry is predicted to dominate majority revenue share of 33% by 2035. The market growth in the region is also expected on account of ever growing energy and power sector. India holds the position of being the world's largest electricity producer. In the year 2022-23, the country witnessed a total electricity generation of 1,844 TWh with utilities contributing 1,618 TWh to this amount. The per capita gross electricity consumption in FY2023 stood at 1,327 kWh. End milling machines are commonly used in the energy sector to produce parts for power plants, such as turbines and generators. They are also widely used to power hydraulic systems, which are essential for many energy-related applications.

North American Market Insights

The North America end milling machine market is estimated to be the second largest, registering a share of about 28% by the end of 2035. The market’s expansion can be attributed majorly to the ever-growing educational institutions and training centers in the region that require end milling machines to teach students and workers how to operate and program CNC machines, creating a continuous demand.

Additionally, as industries expand and develop, more workers need to learn how to use CNC machines, which requires even more end milling machines. As a result, the prices of end milling machines have come down in region, making them more accessible and affordable for both consumers and businesses.

End Milling Machine Market Players:

- WEGOMA

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Hurco

- ATech Machine

- Sibo Engineering

- Kaban Makina

- Yamazaki Mazak

- Elumatec

- Baertec Machinery

- Murat Makina

- Yilmaz Machine

Recent Developments

- Yamazaki Mazak is set to introduce two vertical machines, namely the CVE 600 and VCN 700. These machines offer accuracy, high performance and reduced time consumption for various machining tasks.

- WEGOMA and ITALMAC have embarked on a strategic collaboration to create customized solutions for their customers. This partnership is expected to generate synergies, in the areas of machining centers well as sales and service.

- Report ID: 5196

- Published Date: Sep 11, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

End Milling Machine Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.