Posted Date : 26 September 2025

Posted by : Parul Atri

The construction industry is experiencing a sudden transformation, and Construction 4.0 is effectively leading the charge. It has set its sights on developing smart buildings, robots with laser precision, and AI-driven drones for inspecting sites. This is not science fiction, but is happening at the current moment, including design, build, and maintenance reshape for structures through AI-powered project management. If you are into construction or your focus is on leading-edge technology, then buckle up as we are about to dive into exhilarating progress, from 24/7 robotic personnel and drone swarms for plotting sites in minutes.

But, before we dig deep into these developments, it is crucial for us to gain an insight into Construction 4.0!

What Exactly is Construction 4.0?

Think of the Construction 4.0 concept as the sector’s decisive glow-up, where there is an amalgamation between hard hats and AI. This is not just an upgradation, but a full-blown revolution, big data, robotics, IoT, AI, and automation to convert conventional construction into a sleeker, efficient, and smarter beast. Now picture this: drones mapping sites in 3D, robots laying bricks at rapid speed, and self-healing concrete.

Let us rewind for a second, how did we enter this revolution? Construction 1.0 was all about hand tools! Then there was 2.0, which brought in excavators and cranes; 3.0 unveiled project software and digital blueprints. Now, 4.0 has become the game-changer, wherein machines do not just assist, but they can predict, think, and learn challenges before their occurrence. This is not about a flashy technology; instead, it is about catering to real-world risks, which have skyrocketed worker shortages, expenses, and generated the increasing need for sustainable development. Therefore, the future of construction is not approaching, it is already here, and it is considered smarter than ever before.

Drones in Construction: The Eyes in the Sky

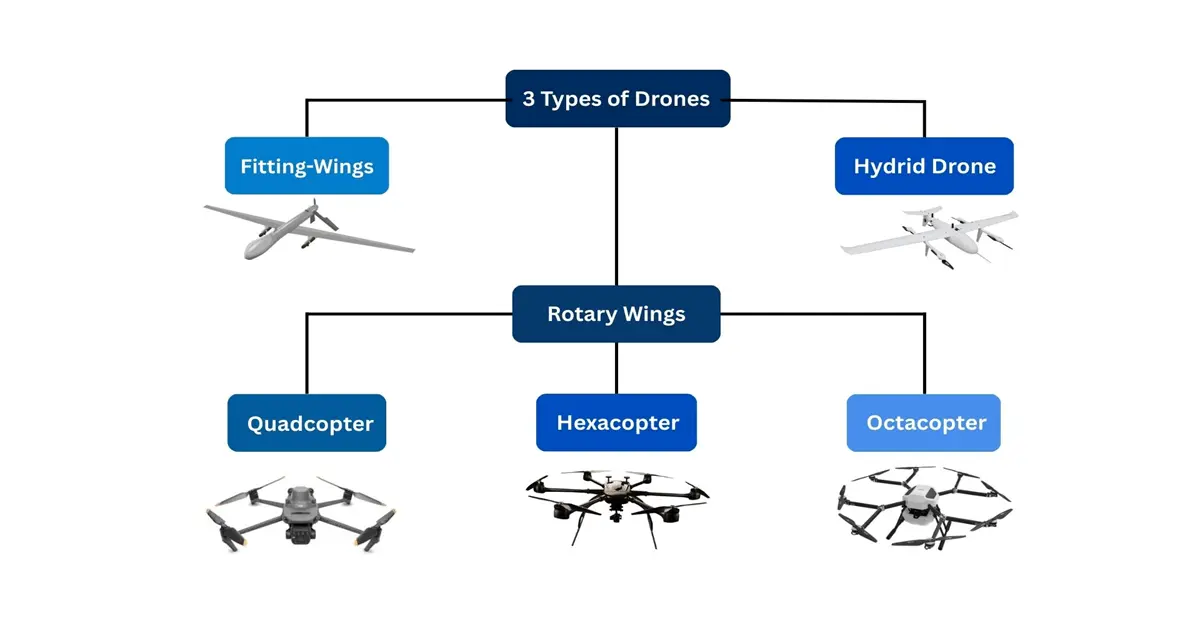

Drones are readily stealing the limelight as construction’s ultimate high-flying sidekick! These are not the usual camera drones for hobbies, but they are high-technology-based workhorses that have revolutionized the development approach. The traditional way of conducting risk assessments and manual measurements is outdated, and this has been replaced with drones that can capture accurate data within minutes. Thereby, this technology has turned exhausting sites into a coffee break and quick operation.

Moreover, there is a breakout of the drone hype, which is due to the following reasons-

- Lightning-fast surveys: What used to take weeks and days now takes place within a fraction of minutes, like just before lunch break wraps up. Drones navigate overall sites with centimeter-level precision, while workforces are still on their second coffee.

- Real-time, bird's-eye oversight: At present, project managers get a live HD update of every concrete, beam, and nail pour without leaving the trailer. This is just like comprising a superpower remote control for construction sites.

- Safety game-changer: Drones boldly visit locations where workers are unable to go and inspect wobbly scaffolding, hover near volatile chemical tanks, and scan collapsed structures. All these activities are useful for keeping the workforce team updated and devoid of any harm while recording data.

Apart from the above-mentioned reasons, the real kicker is that modern drones are not just flying cameras. These are readily equipped with AI-specific analytics, thermal imaging, and LiDAR. These tech-based devices can predict delays, calculate stockpile volumes automatically, and spot micro-cracks in concrete, even before crews are able to notice. Besides, from Turner Construction's daily progress tracking to Skanska's bridge inspections, the sector’s key players have already leveraged drones to save lives, boost accuracy, and slash expenses. The future lies in the aspect that autonomous drone swarms can conduct rapid site audits, and this is what is known as a smarter way of working.

Cutting-Edge Drone Tech Reshaping Construction

In this digitalized and modernized world, construction drones are flying supercomputers which was packed with game-changing technology. Such latest innovations are not just impressive, they are efficiently delivering measurable ROI across different projects. Let us now geek into the latest breakthroughs!

AI-Powered Drones- New Site Supervisors

Modern drones are able to think, analyze, and predict similarly to contractual engineers. For example, Autodesk's Site Scan utilizes machine learning to ensure safety hazards with almost 95.5% accuracy rate. This can readily diminish rework spending by an estimated 17%, particularly for monitored projects. Likewise, Skydio's autonomous drones have leveraged 3D mapping and 6K cameras to navigate complicated sites at 12 mph, while evading cranes. This effectively lowers inspection duration by approximately 85% in comparison to manual methods.

LiDAR Drones- The Ultimate Reality Capture

These drones constitute the capability to shoot approximately 500,500 laser pulses per every second with the objective of developing millimeter-accurate 3D models. For example, mining operations utilize them to calculate stockpile volumes within an estimated 1.5% error margin, as stated in the 2023 USGS report. Meanwhile, Bentley Systems' digital twin integration assists teams to identify clash issues at five times the speed in comparison to conventional CAD reviews.

Swarm Drones- The Construction Avengers

These particular drones constitute a synchronized fleet that can map out more than 95 acres within almost an hour. In addition, these are beneficial and cater to disaster response, along with large-scale audits. For instance, according to the 2023 FEMA government report, after the occurrence of Hurricane Ian, drone swarms effectively assessed more than 220 structures per day. Besides, as per the 2023 NIST report, trials demonstrated that swarms can diminish post-construction verification from weeks to over 45 hours.

Therefore, the bottom line is that with the adoption of AI in construction, drones are anticipated to develop by an estimated 305% by the end of 2027, as predicted by McKinsey in 2023. Additionally, these are USD 15 billion industry disruptors that are suitable for delivering 25% to 45% cost savings on surveys. Thus, the drone evolution is readily suitable for different construction projects by improving site management, recording promotional videos, conducting inspections, and capturing progress image

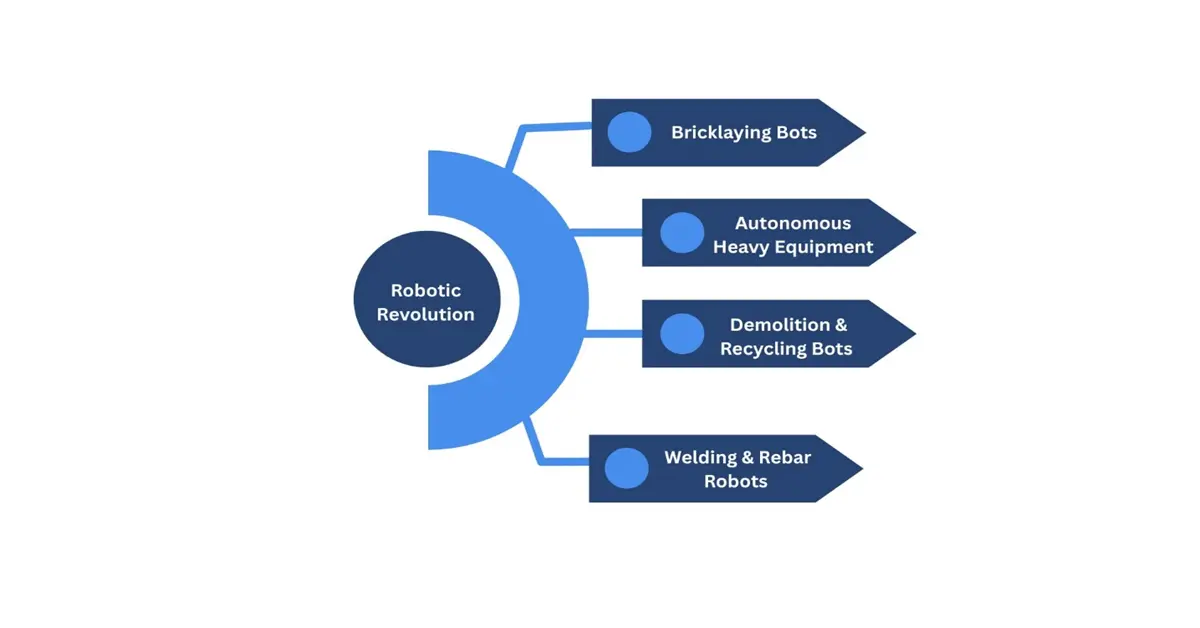

Robotics in Construction- The Rise of the Machines

The future construction site is not just automated, but robot-driven, and the revolution is already existing. These are nothing but mechanical marvels that are converting the sector with game-changing efficiency, relentless productivity, and unmatched precision. Unlike human squads, robots do not require sleep, sick days, and coffee breaks; they just keep on building and developing with flawless accuracy.

Moreover, robotics are able to solve labor shortages, ensure laser-sharp precision, and 24/7 productivity. Robots tend to work day and night, and even during weekends and holidays, which has reduced project timelines by 35%. Besides, bricklaying bots, including SAM100, place blocks within 1.5 mm accuracy, thus diminishing wastage by almost 25% in comparison to manual labor. Likewise, with approximately 82% of contractors struggling to identify skilled workers, robots are stepping in to cater to severe gaps from rebar tying to welding.

Furthermore, these machines are not just assistants, but they are the newest workforce! From 3D printing robots establishing walls in hours to autonomous excavators, these machines are readily positioned in the front seat. With all these benefits, the international construction robotics sector is projected to grow with a valuation of USD 550 million by the end of 2027. Therefore, it can be stated that the bots are here to stay, and they are deliberately building the future by one brick at a perfect time.

Robotic Revolution: The Cutting-Edge Machines Redefining Construction

The upcoming construction industry is crawling with robot-based workers that outperform, outlast, and outpace the human workforce in ways that seem to be science fiction. These are not only prototypes, but field-tested machineries that deliver exclusive results in the present circumstances. Now, let us highlight the game-changers for construction robotics

Bricklaying Bots (Human Hands Just Can't Compete)

These particular construction robots are the ultimate replacement for human workers! For example, SAM100, as a construction robot, is the decisive mason that can lay almost 3,200 bricks per day, with a perfect alignment. This denotes 6.5 times faster than human beings while diminishing material wastage by almost 27.5%. Meanwhile, Hadrian X has taken things much faster! This is a truck-mounted robot that prints an entire house frame with more than 250 blocks per hour. It readily utilizes laser guidance and robotic arms and successfully slashes building times by approximately 65%.

Autonomous Heavy Equipment (No Operators Needed)

Construction-based robots do not require the need of operators while handling heavy equipment. For instance, Built Robotics' AI retrofit kits have transformed suitable excavators into self-driving machines to dig with 2.5 cm GPS precision, and they can operate for straight a week. Besides, Komatsu's smart dozers utilize drone-scanned information to grade land autonomously and achieve millimeter-level accuracy while lowering fuel use by an estimated 18%.

Welding and Rebar Robots (Speed Meets Perfection)

These particular robots not only focus on speed but also consider perfection as the utmost component. For example, TyBot falls under this category and can successfully eliminate backbreaking labor by tying more than 1,000 rebar intersections per day. This caters to 6 times the speed of workers, along with almost 100% accuracy. Likewise, ETH Zurich comprises experimental welding drones that fuel steel beams in mid-air and access critical heights without the need for scaffolding.

Demolition and Recycling Bots (Safety First)

These robot-based bots ensure safety in construction. For example, Brokk’s remote-controlled demolition robots can tear down structures while ensuring more than 2 times the safety of manual workers. Meanwhile, the ERO Concrete Recycler grinds concrete while unravelling rebar for reusability and achieving an estimated 95% of material recovery.

The Future of Construction: Where Drones & Robotics Are Taking Us?

The construction sector is accelerating to achieve a fully autonomous future that can literally make science fiction writers envious. So, just picture this- AI-powered drone swarms readily conducting real-time audits, while robotic crews are operating 24/7 under the supervision of machine-learning workers. There are no coffee breaks, absence of human risks and errors, while effective focus is on hyper-efficient and relentless development.

Furthermore, with the implementation of AI in Construction 4.0, there will be self-healing job sites, wherein equipment failures will be predicted beforehand, and robots will auto-correct errors in between construction processes. In this regard, the MIT, in one of its 2023 reports, demonstrated that construction robots will predict 45% fewer delays by the end of 2030. Meanwhile, human-robot teams will emerge as the ultimate norm, for example, Boston Dynamics’ Spot robots have already inspected hazardous sites in collaboration with manual workers. Likewise, NASA’s RASSOR robots are anticipated to mine moon dirt by 2025 end, while ESA’s 3D-printing bots will fabricate lunar bases by 2030.

The Bottom Line?

Drones and robots are not just tools, they are actually rewriting the rules for construction operations. Key organizations are readily adopting these technologies at the present moment, which in turn, will effectively dominate the upcoming decade. Now, the question is not whether this future will arrive or not, it is will human beings be ready enough when it actually does. One thing is for sure that bots are already existing among us!

Contact Us