Posted Date : 09 October 2025

Posted by : Preeti Wani

In an era where water quality directly impacts public health and industrial efficiency, the safe handling and guarding of water treatment chemicals has become more than a regulatory requirement; it's a necessity for sustainable and secure operations. Whether it's supplying safe drinking water to households or supporting processes in power plants and manufacturing units, the chemicals used in water treatment are essential. They help to eliminate contaminants, prevent corrosion, and maintain water quality standards.

But alongside their utility, these chemicals pose substantial risks if not managed adequately. When storage and handling practices lag, the consequences can be severe, ranging from workplace accidents and environmental damage to legal action and operational downtime. Safe guarding water treatment chemicals is no longer just about fulfilling regulatory expectations; it is about upholding safety, compliance, and sustainability. This article highlights why protecting these chemicals is important, the regulatory standards that govern their use, the hazards of neglect, and best practices undertaken for organizations aiming to protect their workers, assets, and environment.

Understanding the Role of Water Treatment Chemicals

Water treatment chemicals are used to treat and purify water in different sectors, including drinking water facilities, wastewater treatment plants, and industrial cooling systems. These substances include:

- Coagulants and flocculants, such as aluminum sulfate and ferric chloride, which help in aggregating suspended particles.

- Disinfectants like chlorine and chloramine, used to eliminate pathogens.

pH adjusters, including sulfuric acid and lime, that regulate the acidity or alkalinity of water. - Anti-scalants and corrosion inhibitors, such as phosphate compounds, that safeguard pipes and equipment.

- Algaecides and biocides, including copper sulfate and glutaraldehyde, are used to control biological growth.

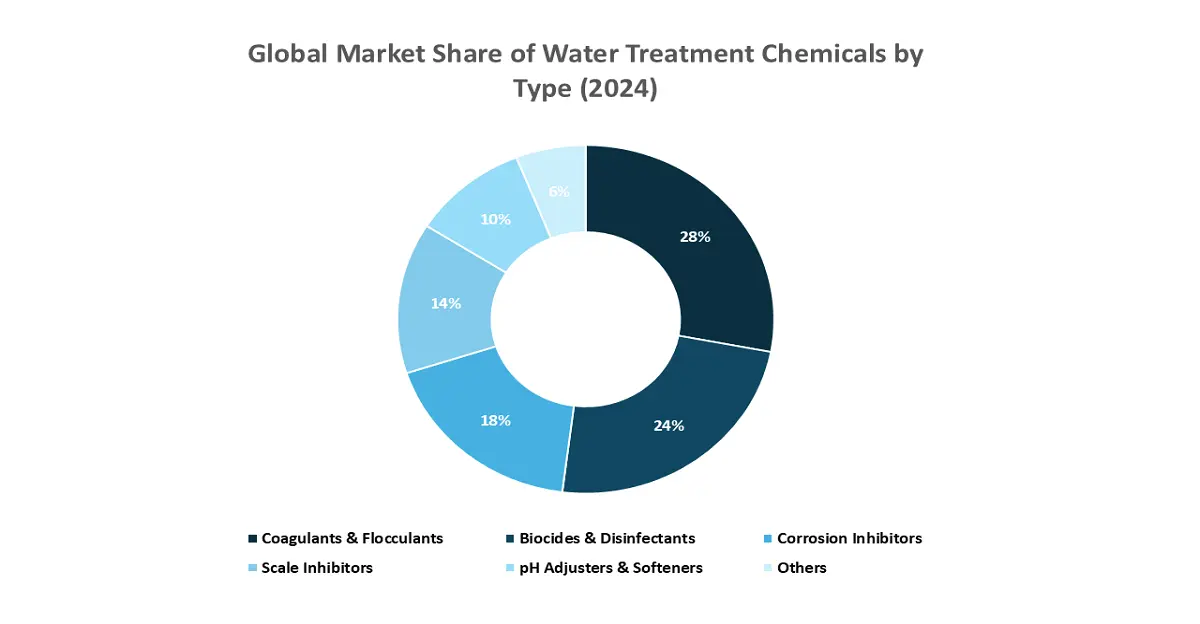

According to a 2024 report by Research Nester, the global water treatment chemicals market stood at USD 40.1 billion and is projected to increase to USD 58.5 billion by 2035. This reflects a steady CAGR of 8.1%, fueled by increasing water stress, urban expansion, and strict quality standards across industries. However, as use expands, so does the obligation to handle these chemicals safely and responsibly.

The Hazards of Poor Chemical Guarding

Despite their benefits, many water treatment chemicals are classified as hazardous. Improper handling or inadequate containment can lead to:

- Toxic exposure, such as inhalation of chlorine gas, can cause respiratory distress.

- Chemical burns and corrosion from strong acids like sulfuric acid, which can hurt skin and eyes.

- Reactivity risks, where mixing incompatible substances results in fires, gas emissions, or explosions.

- Environmental contamination, with spills that contaminate soil, rivers, and groundwater systems.

Guarding these chemicals is not optional; it’s essential. And global regulatory agencies have put strict rules in place to ensure their safe management.

Global Chemical Safety Standards & Regulations Comparison

Organizations that handle water treatment chemicals are subject to a complex and evolving network of local, national, and international regulations. These regulations are made to ensure that chemicals are stored, handled, and transported safely, minimizing risk to human health, the environment, and critical infrastructure. Compliance with these not only protects workers and communities but also secures businesses from legal liabilities, shutdowns, and reputational damage. Below are the key regulations by region and authority.

|

Authority/Framework |

Key Regulations / Standards |

Major Requirements |

Penalties / Enforcement |

|

OSHA – U.S. |

Hazard Communication Standard (29 CFR 1910.1200) |

- Labeling of containers with hazard warnings - Maintain Safety Data Sheets (SDS) - Mandatory staff training - Use of secondary containment (bunds, basins) - Routine inspections and written records |

Up to $16,131 per violation (2024) |

|

EPA – U.S. |

Clean Water Act (CWA), Resource Conservation and Recovery Act (RCRA), SPCC Rule (40 CFR 112), EPCRA |

- SPCC plans for spill prevention - Secondary containment for tanks - NPDES permits for discharge - Reporting of chemical inventories under EPCRA |

Up to $60,973 per day per violation |

|

REACH – EU |

Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH), CLP Regulation |

- Registration of substances >1 tonne/year with ECHA - Chemical Safety Assessments (CSA) - Authorization for SVHCs - Consistent labeling, SDS, and hazard communication per CLP |

Non-compliance can result in import/export bans, product recalls, and heavy fines (varies by EU country) |

|

BIS / IS Codes – India |

IS 10500:2012, IS 299, IS 646, IS 712, IS 16831; Environmental Protection Act (1986); Water Act (1974) |

- Purity standards for treatment chemicals - Safe storage and handling (material compatibility, separation) - Mandatory water quality testing - Spill control and disposal compliance - CPCB guidance and oversight |

Enforcement via CPCB; penalties under EPA 1986 and Water Act 1974 |

Key Components of Effective Chemical Guarding

To ensure the safe use, handling, and storage of water treatment chemicals, organizations must build a robust chemical guarding system. This system not only reduces the chances of accidents but also ensures compliance with regulatory frameworks such as OSHA, EPA, REACH, and BIS. According to a 2024 report by Research Nester, the global chemical storage market was valued at USD 4.9 billion and is expected to register a CAGR of 6.5% through 2035, driven by growing concerns over chemical-related incidents, especially in water and wastewater management. Here are the statistically supported core components of a successful chemical guarding program:

1. Proper Storage: Safe chemical storage is the basis of guarding water treatment substances. Improper storage is responsible for approximately 24% of all chemical incidents, according to the U.S. Chemical Safety and Hazard Investigation Board (CSB).

The Best Practices Include:

- Use of corrosion-resistant tanks: Storage containers made from materials like high-density polyethylene (HDPE), stainless steel, or fiberglass-reinforced plastic are proven to lessen the risk of leaks and degradation by up to 70% over 10 years.

- Segregated storage zones for incompatible chemicals such as acids stored away from oxidizers or bases to prevent chemical reactions. The National Fire Protection Association (NFPA) reports that up to 40% of chemical fires happen due to improper segregation.

- Climate-controlled storage areas: Temperature regulation helps to maintain chemical integrity. A 2019 survey by Dow Chemical showed that nearly 15% of chemical spills in industrial facilities were linked to temperature-induced pressure build-up in containers.

2. Spill Containment and Control: Chemical spills account for one-third of all environmental violations related to water treatment operations, based on EPA compliance records (2022). Proper containment is essential to mitigate these risks. The essential measures include:

- Installation of secondary containment systems such as bund walls, chemical spill pallets, and sump pits that can retain at least 110% of the volume of the largest chemical container, in line with the EPA SPCC Rule (40 CFR 112).

- Convergence of leak detection systems: A study by Frost & Sullivan (2023) estimates that facilities using real-time leak detection sensors saw a 46% reduction in chemical loss incidents.

- Implementation of routine inspection protocols: Establishments performing monthly inspections report 67% fewer containment failures, based on a survey by The Water Environment Federation (WEF).

3. Control and Security: According to the United Nations Environment Programme (UNEP), protecting chemical storage areas prevents theft, tampering, and unauthorized access, which represent 8-10% of chemical safety violations globally.

Security Recommendations:

- Restrict access using RFID-based access cards, biometric scanners, or PIN-controlled systems.

- Use of video surveillance and perimeter fencing lowers the risk of vandalism and theft by over 60%, based on a 2021 study by IFSEC Global.

- Secure internal transport routes to prevent spills during delivery or internal transfers, especially crucial in multi-building facilities. A 2022 AIChE report noted that 18% of chemical mishandling events occur during intra-facility movement.

4. Training and Personal Protective Equipment (PPE): Inadequate training and lack of PPE are the leading reasons for injury in chemical handling environments. OSHA states that 33% of chemical-related injuries are due to insufficient worker protection and training.

Key Recommendations:

- Perform annual or bi-annual training sessions on chemical handling, emergency shutdown procedures, and spill response.

- Provide certified PPE, such as nitrile gloves, face shields, acid-resistant aprons, and full-face respirators.

- Build a trained in-house emergency response team (ERT): Facilities with dedicated ERTs respond to chemical incidents 75% faster than those depending purely on external responders.

5. Labeling and Signage: Mislabeling or lack of safety instructions accounts for nearly 20% of chemical exposure incidents, as per the Chemical Safety Board (CSB).

Compliance Requirements:

- Every chemical container must be labeled with its name, concentration, hazard class, and emergency contact information.

- Use Globally Harmonized System (GHS)-compliant pictograms, including signal words like Danger or Warning.

- Mark storage zones and emergency exits. Facilities that employ standardized hazard signage report 42% fewer compliance violations, based on a 2023 review by SafetyCulture.

Cost of Non-Compliance

Non-compliance with chemical guarding standards can have significant financial consequences.

- The average cost of a single chemical spill in an industrial infrastructure is near about USD 110,000.

- Frequent safety violations can result in cumulative fines of over USD 500,000 annually.

- Facilities that invest in full-scale chemical guarding systems see an average ROI of 2.3x over five years due to reduced incidents, insurance claims, and downtime.

Industry Best Practices for Guarding Water Treatment Chemicals

To mitigate risks associated with water treatment chemicals, industries worldwide adhere to structured safety protocols developed from years of incident analysis and evolving compliance standards. Implementing these industry best practices not only strengthens workplace safety but also reduces legal liability, environmental risks, and operational downtime. Here are some industry-verified best practices for protecting water treatment chemicals:

- Create a Chemical Hygiene Plan (CHP): A critical first step is the creation of a Chemical Hygiene Plan (CHP), a written safety protocol that outlines how hazardous chemicals are handled, stored, and responded to in case of emergencies. According to OSHA, workplaces with an established CHP face 38% fewer exposure incidents. These plans not only define responsibilities and procedures but also incorporate training, PPE guidelines, ventilation protocols, and first-aid responses. Facilities that review their CHP annually, as recommended by the American Chemical Society, see even greater gains in safety performance.

- Perform a Risk Assessment: By evaluating each chemical’s Safety Data Sheet (SDS), analyzing compatibility, and identifying potential hazards, organizations can make better decisions about storage methods, ventilation needs, and emergency planning. The National Safety Council states that performing routine chemical risk assessments leads to a 50% cut in workplace accidents. A 2022 study published by Chemical Processing Magazine found that companies conducting quarterly risk assessments experienced 40% fewer near-miss incidents compared to those that only reviewed their processes annually.

- Develop an Emergency Response Plan: A well-developed Emergency Response Plan (ERP) is another cornerstone of chemical guarding. This plan should entail coordination with local fire departments, emergency medical services, and HAZMAT response teams. The EPA and FEMA jointly report that establishments with tested ERPs respond to emergencies 68% faster than those without. Additionally, NFPA data shows that ERP-coordinated responses reduce the likelihood of off-site environmental damage by 65%. Key elements include annual emergency drills, accessible eyewash stations, and spill control kits pre-stocked with neutralizing agents.

- Regular Audits and Compliance Checks: To ensure that safety protocols are continuously well-maintained, organizations must conduct regular audits and compliance checks. According to Industrial Safety & Hygiene News (ISHN), facilities performing scheduled audits experience a 71% improvement in compliance scores.

- Implement Digital Logbooks: Modern organizations are also adopting digital logbook systems to improve traceability and accountability. Replacing paper-based records with cloud-based platforms helps teams to track chemical usage, monitor storage conditions, and log inspection data in real-time. The International Society for Automation (ISA) adds that digitizing chemical management fewer administrative workload by 55%, freeing safety teams to focus on preventive measures and compliance planning.

Contact Us