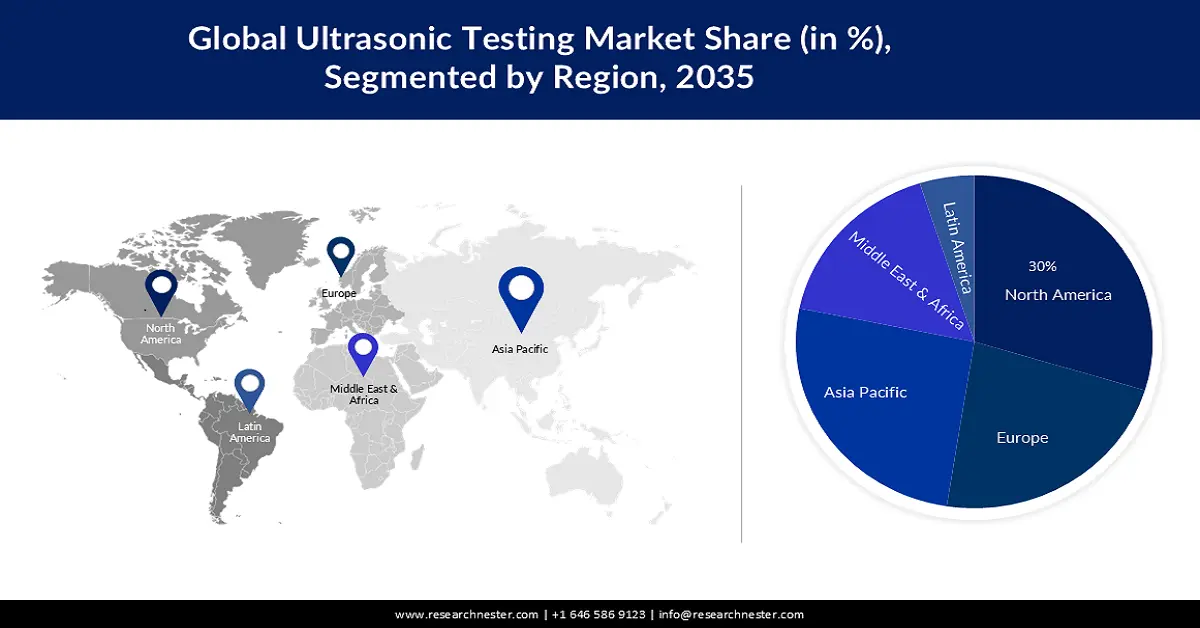

Ultrasonic Testing Market Regional Analysis:

North America Market Insights

The North America ultrasonic testing market is expected to hold a share of 30% during the analysis period. This growth is attributed to the rising industries' focus on safety regulations and quality standards. Companies in aerospace, automotive and energy sectors, are currently facing more regulatory demands, thus they prefer non-destructive UT techniques to maintain compliance. The detection of internal structural defects by UT technology ensures material safety through non-destructive testing, which simultaneously minimizes operational risks, thus making it vital for maintaining compliance with quality standards in the manufacturing facilities.

The market in the U.S. is expected to grow at a steady pace, owing to the modernized industrial infrastructure and mandatory preventive maintenance. The expansion of industries such as oil & gas, power generation, and transportation requires dependable non-destructive testing methods to ensure reliable asset inspections. Real-time, accurate results and nondestructive capabilities of UT prevent substantial downtimes and early issue detections, leading to longer critical asset lives, thus propelling the market.

The rising emphasis on environmental and sustainability is also boosting the market growth. Ultrasonic testing emerges as the most appropriate solution for critical infrastructure monitoring as it uses non-destructive methods to assess components while maintaining full environmental compliance. UT enables industries to accomplish regulatory requirements while minimizing environmental impacts of their operations, particularly when quality materials and structures maintain sustainability standards in the construction, aerospace, and energy sectors.

Asia Pacific Market Insights

The ultrasonic testing market in Asia Pacific is expected to hold a share of 26% during the stipulated timeframe. The market experiences strong growth due to increasing automation and digitalization initiatives. The adoption of Industry 4.0 technology, along with advanced manufacturing methods and automated inspection tools, is making industries depend on ultrasonic testing for real-time quality control functions. Ultrasonic testing, when combined with automated production lines, delivers operational improvements while decreasing human errors and producing better quality products, thus making it crucial for various industries.

The market in China is all set to witness rapid growth, due to rising manufacturing sector. China upholds its position as the world's top manufacturer while currently experiencing an increase in advanced non-destructive testing methods needed to verify product quality and operational efficiency. Industries such as automotive, electronics, and heavy machinery depend largely on ultrasonic testing owing to its importance in maintaining product precision. Manufacturers are adopting ultrasonic testing technologies to discover underlying material flaws without material destruction, as production safety regulations and quality control needs are continually expanding.

Continuous expansion of infrastructure construction projects across transportation and energy development, alongside construction works, is resulting in a rising demand for ultrasonic testing. The substantial investments in infrastructure development are propelling the requirement for effective inspection tools for materials, welds, and pipelines. Ultrasonic testing represents an efficient yet budget-friendly non-destructive method for maintaining critical infrastructure components such as bridges and tunnels, as well as pipelines throughout the massive infrastructure growth.