Cast Polymers Market Outlook:

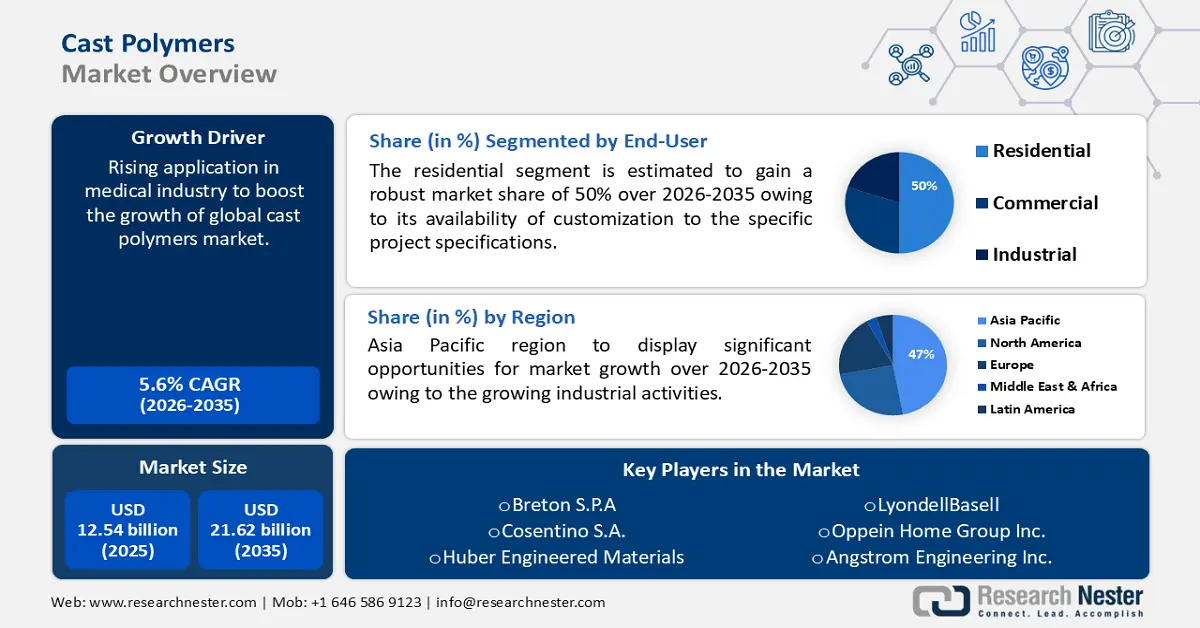

Cast Polymers Market size was over USD 12.54 billion in 2025 and is anticipated to cross USD 21.62 billion by 2035, growing at more than 5.6% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of cast polymers is assessed at USD 13.17 billion.

The reason behind the growth is due to the growing spending in the construction sector across the globe, leading to increasing development of residential and commercial settings which is expected to fuel the demand for construction materials such as cast polymers.

Construction spending is predicted to reach around USD 17 trillion globally by 2030, with the US, China, and India leading the way and contributing over 55% of the growth in this sector.

The growing popularity of aesthetically pleasing interiors is believed to fuel the market growth. This could be significant among the GenZ population. Hence, with the surging Generation Z population the demand for cast polymers is growing since it offers aesthetic appeal. As a result, the revenue for the cast polymers market is set to rise.

Key Cast Polymers Market Insights Summary:

Regional Highlights:

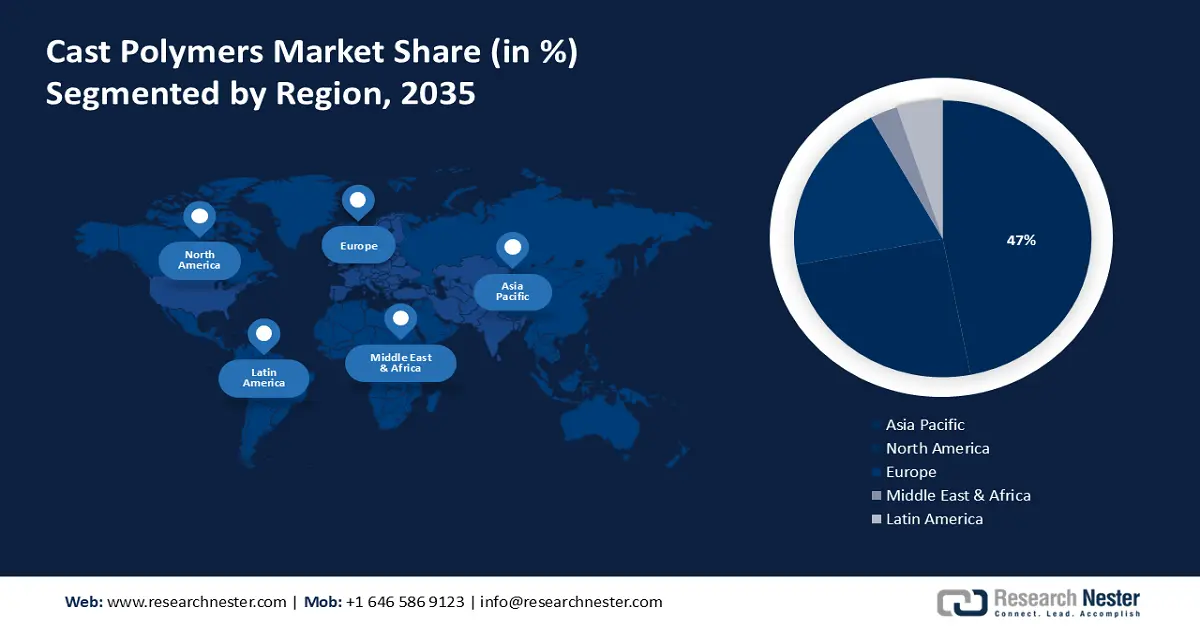

- The Asia Pacific cast polymers market is expected to capture 47% share by 2035, fueled by increasing industrial activity and fast industrial production growth.

Segment Insights:

- Residential segment in the cast polymers market is forecasted to achieve 50% growth by the forecast year 2035, driven by rising demand from home remodeling projects due to the durability and moldability of cast polymers.

- The countertops segment in the cast polymers market is projected to hold a 32% share by 2035, attributed to the increasing number of residential houses requiring kitchen and bathroom surfaces.

Key Growth Trends:

- Increasing popularity of casting resins

- Adoption of sustainable practices

Major Challenges:

- Presence of alternatives such as natural stone and wood

- The expensive cost of cast polymers due to the involvement of intricate molds and skilled labor impedes market growth

Key Players: R.J. Marshall Company, E. I. Du Pont De Nemours and Company, Swan Corporation, Link Composites Pvt. Ltd., Cosentino S.A., Oppein Home Group Inc., Huber Engineered Materials, Breton S.P.A, Danimer Scientific, Inc., Angstrom Engineering Inc., Sto SE & Co. KGaA, LyondellBasell.

Global Cast Polymers Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 12.54 billion

- 2026 Market Size: USD 13.17 billion

- Projected Market Size: USD 21.62 billion by 2035

- Growth Forecasts: 5.6% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (47% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: United States, China, Germany, Japan, India

- Emerging Countries: China, India, Malaysia, Thailand, Indonesia

Last updated on : 11 September, 2025

Cast Polymers Market Growth Drivers and Challenges:

Growth Drivers

- Rising applications in medical industry - Cast polymers impede the development of mold and bacteria and are considered hygienic which makes them perfect for use in medical facilities.

Additionally, hospital-acquired infections are at hike which makes it necessary to adopt effective solutions to maintain hygiene. For instance, according to the World Health Organization, every 7 patients out of 100 patients in acute-care hospitals in high-income countries along with 15 patients in low- and middle-income nations is predicted to acquire at least one HAI during their hospital stay. Hence, the cast polymers market is projected to grow over the years to come. - Growing marine sector - Ships are usually prone to high risk of corrosion which might further cause huge loss of revenue and environment. Hence, cast polymers are often used in the marine sector owing to their water-resistant properties.

- Increasing popularity of casting resins - Epoxy resin coatings and casting are two different yet related substances that are used in the production of rubber, ABS, polypropylene, acrylic, nylon, and glass-filled nylon as they are an extremely resilient polymer that is resistant to deterioration from water and other environmental elements. Therefore, the cast polymers market revenue is set to rise.

- Adoption of sustainable practices - Cast polymer materials support environmental objectives as these products are manufactured from recycled materials, and have a longer lifespan, which eventually results in lower maintenance and replacement expenses making them an environmentally friendly option for building projects. As a consequence, the market is poised to have the highest growth in its revenue.

Challenges

- Presence of alternatives such as natural stone and wood - Many individuals believe that stone, which includes granite, marble, limestone, travertine, slate, and sandstone, performs better than a solid surface. It has always been regarded as a superior building material that embodies grandeur, character, and solidity. Natural stone is widely acknowledged as a durable, solid, and ageless building material that has been utilized in the construction of renowned historical buildings, monuments, and artwork worldwide.

Additionally, wood offers exceptional barrier qualities and is free from toxins, allergies, isocyanates, plastic additives, latex, or dust. - The expensive cost of cast polymers due to the involvement of intricate molds and skilled labor impedes market growth.

- Varying prices of raw materials such as fiberglass and aluminum trihydrate may increase the overall cost of production.

Cast Polymers Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

5.6% |

|

Base Year Market Size (2025) |

USD 12.54 billion |

|

Forecast Year Market Size (2035) |

USD 21.62 billion |

|

Regional Scope |

|

Cast Polymers Market Segmentation:

End-User Segment Analysis

The residential segment in the cast polymers market is set to garner a notable share of about 50% over the forecast period. Products made of cast polymer are mostly utilized in residential settings, as the majority of the rise in demand for cast polymers is attributed to home remodeling projects, as they can be molded into surfaces for sinks, shower walls, bathtubs, and even window sills and are less prone to damage and discoloration than natural marble and stone. Therefore, with the rising segment growth, the cast polymer market is also predicted to increase.

Besides this, the demand for cast polymer materials used in commercial construction, including public utilities such as schools, hospitals, and transit facilities, is rising globally. Cast polymer products are easy to maintain and available in a range of colors and styles, which makes them the best option for large hotel chains and stores.

Application Segment Analysis

The countertops segment is estimated to account for 32% share of the global cast polymers market by 2035 impelled by the increasing number of houses. This growth of the segment is set to be encouraged by the rising number of residential houses. For instance, according to estimates, in 2021, more than 302 million homes were in India. However, every new home requires kitchen and bathroom surfaces which are expected to boost the demand for a countertop that is also referred to as a bunker, counter, benchtop, worktop, or kitchen bench.

These countertops are often made from cast polymers such as cultured marble, onyx, and solid surfaces, which are self-structural resist breaking, and are simple to maintain.

Moreover, cultured marble vanity tops provide a smooth, multipurpose look and cost less than granite. They are one of the most fashionable countertop options, which is highly recommended by both interior designers and homeowners. Besides this, onyx is one of the priciest natural stone countertops and is a popular choice for homeowners seeking a material that resembles marble. Hence, owing to the growing availability of different materials and rising preference for them the segment is predicted to experience a rise. As a result, the market is also projected to rise.

Material Segment Analysis

The alumina trihydrate segment is anticipated to gain a noteworthy market share during the forecast timeframe. Cast polymers are composed of several types of polymeric ingredients, including alumina trihydrate, which is the most commonly used flame retardant in the world. It is an odorless, inert filler powder that comes in various uncoated and coated grades and is mostly used to increase the weight and lessen the shrinkage of cast polymer products.

Type Segment Analysis

The engineered stone segment in the cast polymers market is poised to gain a remarkable revenue share. Engineered stone is made by combining natural stone components with polymer casting resins, which are the most durable cast polymer products that possess excellent stain and scratch resistance, low thermal expansion, and strong heat resistance.

Additionally, a solid surface is a synthetic substance that can be designed to resemble actual granite and is frequently employed in the production of goods, including kitchen countertops.

Our in-depth analysis of the global market includes the following segments:

|

Material |

|

|

Type |

|

|

End-User |

|

|

Application |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Cast Polymers Market Regional Analysis:

APAC Market Insights

Driven by increasing industrial activity, the cast polymer market in Asia Pacific is expected to hold the biggest share of 47% by 2035. India's economy is already the fastest-growing in the world, and it is seeing the fastest pace of industrial production growth within the region.

Additionally, China's industrial activities grew more quickly than anticipated since the country increased its industrial production in October 2023, by more than 4%. For instance, in September 2023, India's industrial production grew by over 5% compared to the same month the previous year.

North American Market Insights

The North American cast polymers market is estimated to be the second largest during the forecast timeframe, led by the increasing focus on eco-friendly solutions. Companies in the region are facing increasing pressure to behave in a more socially and environmentally responsible manner, as a result of which more businesses are considering environmental friendliness as a key goal for their operations and strategies to boost growth and global competitiveness and improve operational effectiveness by cutting expenditures and waste.

Cast Polymers Market Players:

- R.J. Marshall Company

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- E. I. Du Pont De Nemours and Company

- Swan Corporation

- Link Composites Pvt. Ltd.

- Cosentino S.A.

- Oppein Home Group Inc.

- Huber Engineered Materials

- Breton S.P.A

- Danimer Scientific, Inc.

- Angstrom Engineering Inc.

- Sto SE & Co. KGaA

- LyondellBasell

Recent Developments

- Danimer Scientific, Inc. together with Chevron Phillips Chemical to investigate the creation and marketing of cast extrusion films by utilizing Rinnovo polymers a type of polyhydroxyalkanoate to quicken the process of implementing Rinnovo materials in high-volume applications.

- SABIC (Saudi Arabia Basic Industries Corporation) teamed up with Aramco and TotalEnergies to create circular polymers from plastic pyrolysis oil to aid in the creation of a domestic value chain for the better recycling of plastics, and allow the usage of non-sorted polymers.

- Report ID: 5475

- Published Date: Sep 11, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Cast Polymers Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.