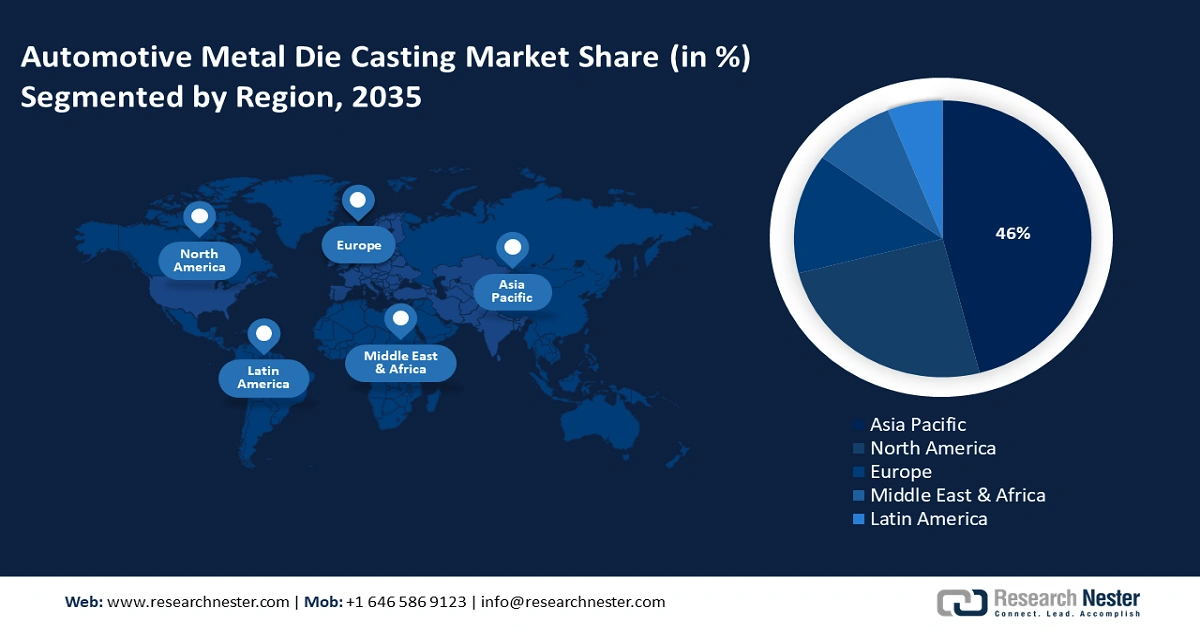

Automotive Metal Die Casting Market Regional Analysis:

Asia Pacific Market Insights

The automotive metal die casting market in Asia Pacific is projected to hold the highest share of 46% by 2035, owing to the region's expanding automotive industry and increasing demand for lightweight components. This growth is further fueled by the increasing adoption of EVs, which demand lightweight materials, including aluminum, to optimize energy efficiency and reduce emissions. Additionally, advancements such as high-pressure die casting technology are helping in the production of complicated and precise automobile parts, expanding the market.

The automotive metal die casting market in China is witnessing significant growth due to the robust manufacturing potential, supportive government policies, and investments for EV production. According to a report, in 2022, China sold more than 6 million EVs, marking an 82.33% surge from 2021. This sudden surge in EV sales has escalated the demand for high-pressure castings, particularly in areas of transmission, powertrain, and battery housings. Manufacturers in China are investing in advanced die-casting machines to meet this demand, keeping the country a global leader in automotive metal die casting.

The automotive metal die casting market in India is predicted to hold a notable share due to the rising automotive production. The growth can be attributed to government initiatives such as the Production-Linked Incentive (PLI) scheme and rising demand for lightweight components in vehicles. The PLI scheme in India, with a budget of USD 3.5 billion, is targeted to promote domestic production of high-tech automotive products and attract investments to the industry. This supportive background is encouraging innovation and investment in the die-casting sector, increasing its competitive edge worldwide.

North America Market Insights

The automotive metal die casting market in North America is projected to hold a significant share of 25% by 2035, driven by rising investments in electric vehicle manufacturing and advanced production technologies. Industry players in North America are upgrading their facilities to meet the evolving vehicle efficiency regulations. Moreover, the shift to aluminum die casting type is helping automobile manufacturers to lower overall vehicle weight and reduce vehicle emissions, complying with environmental regulations.

In the U.S., the automotive metal die casting market is driven by strong government support for clean energy vehicles and domestic auto production. Initiatives such as the Inflation Reduction Act and EV tax credits in the country have boosted the demand for lightweight metal parts and pressure-cast metal parts. Thus, U.S. manufacturers are investing in high-pressure die casting to improve output and quality.

Canada automotive metal die casting market is expanding as automakers rely more on local sourcing of parts and work on building cleaner, more optimized vehicles. Moreover, support from the government’s zero-emission vehicle program increases demand for lightweight aluminum castings. This push is encouraging more innovation and automation in the die casting process.