Welding Fume Extraction Equipment Market Outlook:

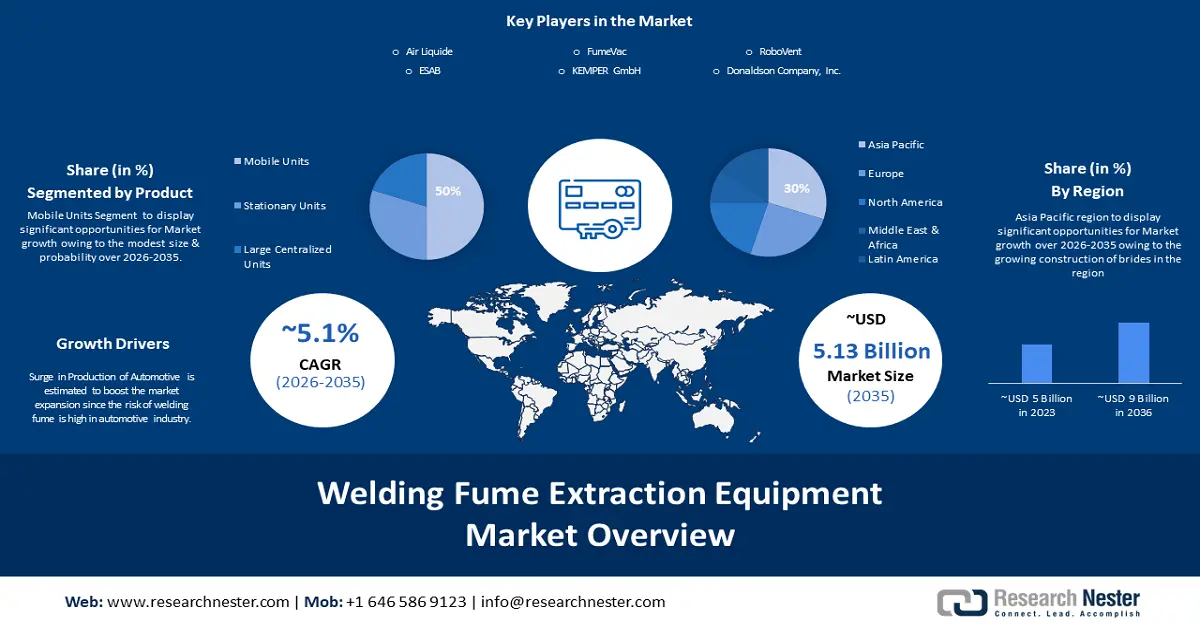

Welding Fume Extraction Equipment Market size was over USD 3.12 billion in 2025 and is poised to exceed USD 5.13 billion by 2035, growing at over 5.1% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of welding fume extraction equipment is estimated at USD 3.26 billion.

This growth of the market is poised to be influenced by rising construction activities. There was a projection of 794,431 built-up areas (BUAs) around the world in 2016. It has been projected that this figure would rise to approximately 849,406 inhabitants by 2022. In addition, it's anticipated that by 2050, more than two million additional structures are scheduled to be developed. These construction activities are estimated to increase demand for welding.

In the construction sector, welding technologies are extensively employed, mostly to join different metal components to create structurally sound metal frameworks. Hence, with this, the adoption of welding fume extraction equipment is also projected to rise to protect workers from harmful fumes. Furthermore, throughout the forecast period, strict restrictions imposed by different regulatory bodies to lower the hazards of exposure to hazardous fumes are expected to fuel demand for welding fume extraction equipment.

Key Welding Fume Extraction Equipment Market Insights Summary:

Regional Highlights:

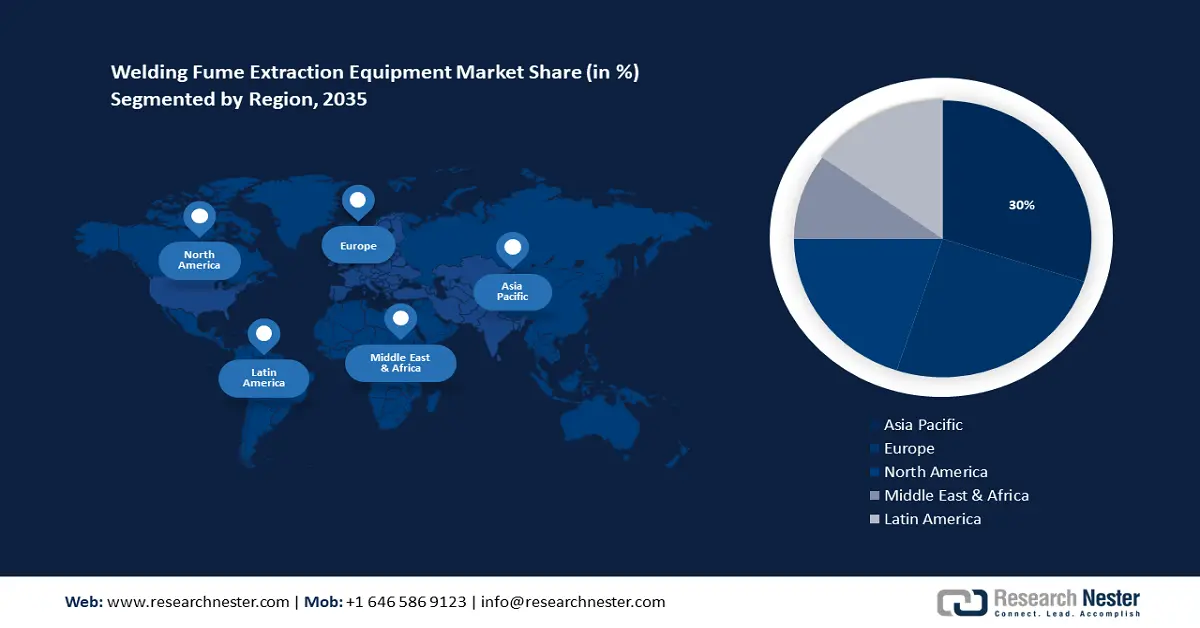

- The Asia Pacific welding fume extraction equipment market is expected to capture 30% share by 2035, attributed to rising urbanization and oil & gas infrastructure projects.

- The North America market will achieve significant CAGR during 2026-2035, driven by the growing demand for electric vehicles and health awareness.

Segment Insights:

- The mobile

- The arc welding segment in the welding fume extraction equipment market is poised for substantial growth through 2035, driven by growing demand for automotive applications.

Key Growth Trends:

- Surge in Production of Automotive

- Growing Deployment of IoT & Smart Features

Major Challenges:

- Require High Operational & Maintenance Costs

Key Players: Vitesco Technologies GmbH, Donaldson Company, Inc., KEMPER GmbH, Nederman Holding AB, RoboVent, Diversitech Equipment & Sales Ltd., Air Liquide, ESAB, Lincoin Electric Company, FumeVac.

Global Welding Fume Extraction Equipment Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 3.12 billion

- 2026 Market Size: USD 3.26 billion

- Projected Market Size: USD 5.13 billion by 2035

- Growth Forecasts: 5.1% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (30% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: Germany, United States, China, Japan, United Kingdom

- Emerging Countries: China, India, Japan, South Korea, Thailand

Last updated on : 16 September, 2025

Welding Fume Extraction Equipment Market Growth Drivers and Challenges:

Growth Drivers

- Surge in Production of Automotive - Throughout the globe, over 84 million motor vehicles were built in 2022—about 4% growth over 2021. Additionally, these automobiles have several welds below. Given its direct correlation with passenger safety, welding is of utmost importance in the automotive industry. A vehicle's appearance and dependability are enhanced by neat, robust welds, which add to its overall quality and safety. As a result, the adoption of welding fume extraction is also estimated to surge.

- Growing Deployment of IoT & Smart Features - The sectors that operate, interact, and consume data have all changed dramatically as a result of the deployment and growing use of the internet of things (IoT). More than 74 billion devices are expected to be connected via IoT by 2025, globally. The capacity to automate and hence maximize operating efficiency is the largest advantage of IoT for manufacturers. Through the use of Internet of Things sensors and connections, extraction equipment may collect data on operational parameters, equipment performance, and air quality in real time. Data analytics also provide information for predictive maintenance, extraction process optimization, and proactive decision-making. This ingenious integration boosts productivity, reduces downtime, and enhances worker safety by ensuring timely maintenance and effective fume extraction, which drives the welding fume extraction equipment market.

- Rising Construction of Ships - Ships have long been a big part of our daily life, from recreational activities to transporting the great majority of all traded items worldwide. As a result, the shipbuilding activities are growing. Furthermore, shipbuilders benefited greatly from the replacement of riveting with welding since it resulted in lighter structures, smoother surfaces, and increased efficiency. As a result, welding is currently regarded as one of the shipbuilding industry's most often-used hot-work techniques. However, the biggest health danger to a welder working in the shipbuilding industry is exposure to hazardous welding fumes, if proper precautions are not taken. Therefore, the welding fume extraction equipment market demand is projected to experience growth over the coming years.

Challenges

- Require High Operational & Maintenance Costs - Routine maintenance, which includes filter replacements and system servicing, may be expensive and time-consuming, especially for larger industrial settings. Energy use and running expenses for the upkeep of extraction systems also have an impact on the total cost burden. These outrageous costs may deter some companies from investing in fume extraction equipment, putting employee safety and compliance with health and safety regulations at risk.

- Growing Difficulty in Retrofitting Facilities that Already Exist - Existing infrastructure and layouts might render the installation of extraction systems difficult, which would increase costs and provide logistical difficulties. It's usually tough to integrate with out-of-date gear and software, which calls for adjustments that reduce usefulness and raise expenses. Efficient fume extraction systems in existing buildings are challenging for firms to install due to space limits and regulatory compliance requirements, which further complicate the retrofitting process.

- Lack of Awareness Regarding Its Use

Welding Fume Extraction Equipment Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

5.1% |

|

Base Year Market Size (2025) |

USD 3.12 billion |

|

Forecast Year Market Size (2035) |

USD 5.13 billion |

|

Regional Scope |

|

Welding Fume Extraction Equipment Market Segmentation:

Product Segment Analysis

The mobile units segment in the welding fume extraction equipment market is projected to gather the highest revenue share of over 50% in the coming years. Due to their wheeled design, mobile welding fume extractors are simple to move throughout the workshop to wherever extraction is required. Given their modest size and portability, mobile units are perfect for small fabrication and welding operations that require light- to medium-duty welding fume extractors. This equipment are additionally suitable for welding and fabrication jobs on occasion, as well as tight spaces including ship hulls, tanks, and difficult-to-reach areas. The ideal solution is mobile equipment if the welding is done in several locations. For metalworking companies, they are a useful and transportable option owing to their ability to remove dangerous gases from the workplace.

Application Segment Analysis

The arc welding segment for the welding fume extraction equipment market is set to generate the highest revenue revenue of about 40% during the forecast period. Arc welding is one method of joining metal that is frequently used, and it is essential for constructing steel structures and machinery for instance in automotive. Hence, with the growing demand for automotive the segment growth is flourishing. For instance, global auto sales went up from over 66.7 million vehicles in 2021 to somewhere around 67.2 million vehicles in 2022. The technique of arc welding creates an electric arc between an electrode and the base metal. To form the weld metal required to join structural components, the heat from the arc melts the base metal and the welding consumable. There are various types of arc welding techniques, including submerged arc welding, plasma arc welding, gas-shielded metal arc welding, gas tungsten arc welding, self-shielded arc welding, and electro-gas arc welding. A filler metal that provides the deposited metal for the weld and an electrode that forms the arc are the consumables in the consumable-electrode welding method.

Our in-depth analysis of the global market includes the following segments:

|

Product |

|

|

Application |

|

|

Vertical |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Welding Fume Extraction Equipment Market Regional Analysis:

APAC Market Insights

Asia Pacific industry is expected to account for largest revenue share of 30% by 2035. This growth of the market is set to be influenced by the growing construction of bridges and social infrastructure. Additionally, this region is also experiencing rise in its urban population. Roughly 2.2 billion people, or 54% of the globe's metropolitan population, reside in Asia. Asia's urban population is poised to rise by 50% by 2050, adding 1.2 billion new residents. The ongoing onshore and offshore oil and gas exploration operations in the Asia Pacific region, as well as the ongoing construction projects for refining pipelines, are also contributing to the market's growth.

North American Market Insights

The North America welding fume extraction equipment market is also estimated to have significant growth in coming years. The major element to dominate the market expansion in this region is the growing demand for electric vehicles as a means of reducing their carbon footprint. The growing awareness among companies and employees of the health risks associated with welding emissions is another factor driving market demand in this region. Technological advancements in extraction equipment and growing investments in industrial and infrastructure projects are other factors propelling market growth in this region.

Welding Fume Extraction Equipment Market Players:

- Vitesco Technologies GmbH

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Donaldson Company, Inc.

- KEMPER GmbH

- Nederman Holding AB

- RoboVent

- Diversitech Equipment & Sales Ltd.

- Air Liquide

- ESAB

- Lincoin Electric Company

- FumeVac

Recent Developments

- Leading global producer of cutting-edge drive technologies and electrification solutions, Vitesco Technologies, uses cutting-edge laser systems from its reliable production engineering partner, TRUMPF. Vitesco Technologies is one of the leaders in the serial use of this novel technology with the launch of the new green laser equipment for copper welded joints. When using green lasers instead of infrared laser systems, which are currently the industry standard for copper welding, energy consumption can be reduced by up to 20%, depending on the application, and subsequently the CO2 footprint per laser-welded joint. Green laser systems almost completely eliminate copper spatter during welding, which would otherwise require extra labour throughout manufacturing, making production more sustainable.

- Donaldson Company, Inc., a leading global developer of innovative filtration products and solutions, has introduced the Torit Downflo Ambient (DFA) weld fume extractor, which enables fabricators to weld in a number of workstation layouts.

- Report ID: 5874

- Published Date: Sep 16, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.