Predictive Maintenance Market Outlook:

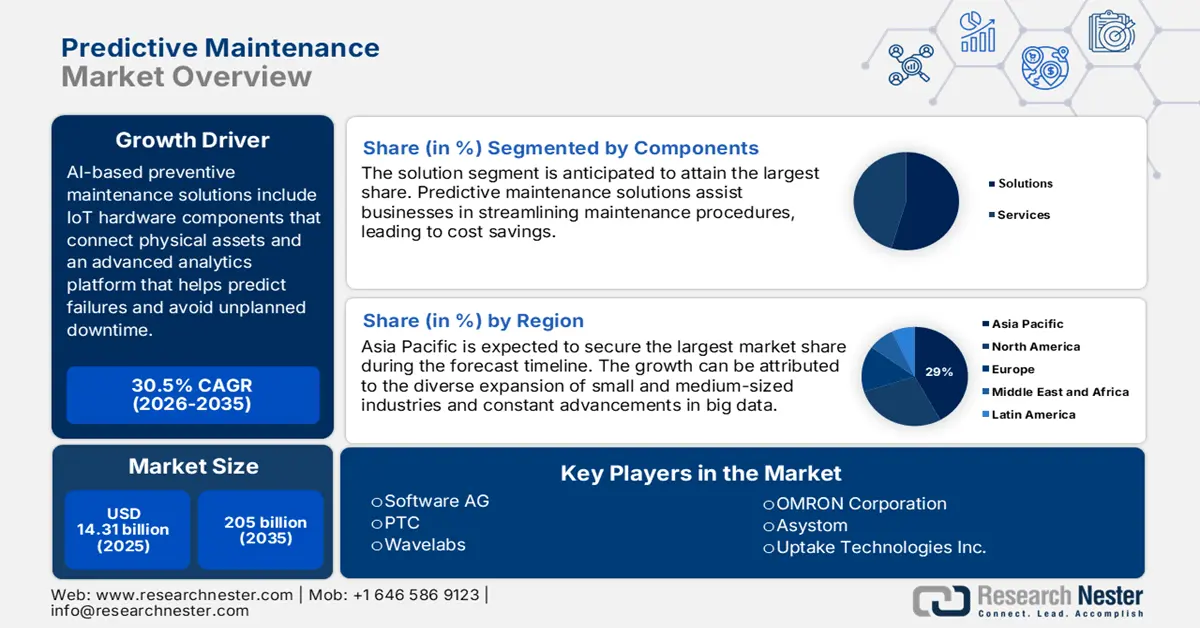

Predictive Maintenance Market size was valued at USD 14.31 billion in 2025 and is expected to reach USD 205 billion by 2035, expanding at around 30.5% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of predictive maintenance is evaluated at USD 18.24 billion.

The growth of the market can be attributed to the growing need to reduce downtime and maintenance costs. Predictive maintenance predicts the best time for the maintenance of the equipment which also makes the maintenance procedure cost-effective, therefore it reduces the wastage of time and resources on the occasion of machine breakdown. Large factories lose 323 productivity hours annually on average. The average cost of lost sales, fines, downtime for employees, and restarting production lines is USD 532,000 per hour, or USD 172 million per facility yearly.

In addition to these, factors that are believed to fuel the market growth of the predictive maintenance market include digital transformation taking place in the organization is boosting the company’s progress along with the data consumption and production. The digital transformation of industries into industry 4.0, has introduced new predictive maintenance methods which are creating a new concept known as Maintenance 4.0. Organizations that have undergone digital transformation are anticipated to generate more than half of the global GDP by 2023. Moreover, every day, it is estimated that 1.145 trillion MB of data are produced. Around 300 billion emails were sent daily in 2022. Users sent about 650 million Tweets daily in 2022.

Key Predictive Maintenance Market Insights Summary:

Regional Highlights:

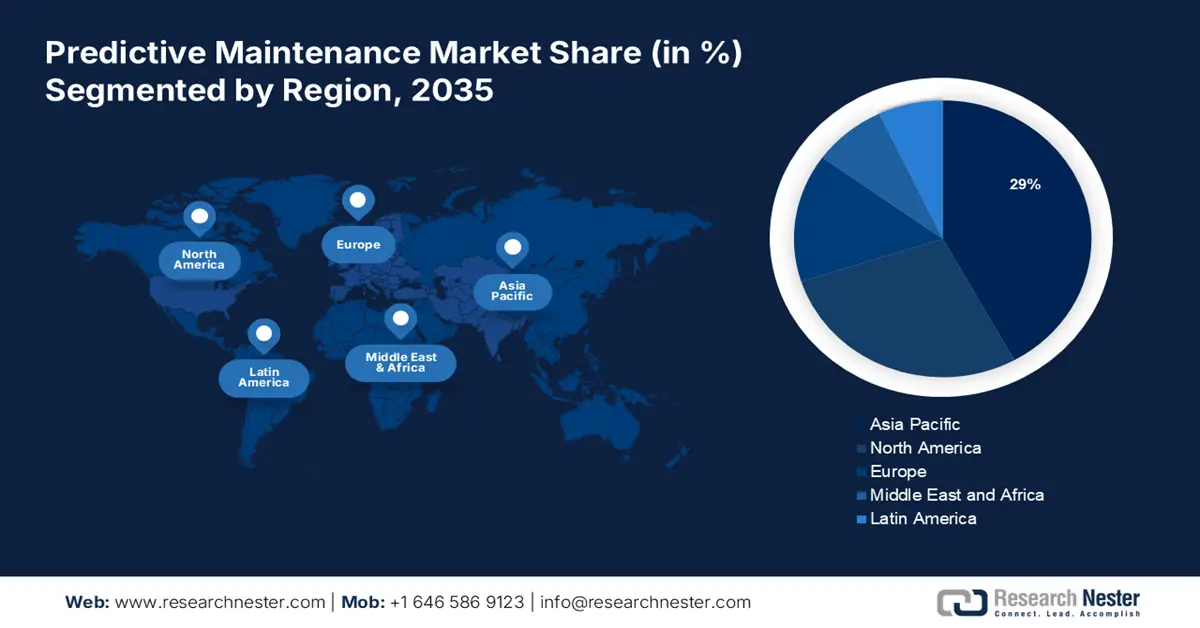

- Asia Pacific predictive maintenance market will secure around 29% share by 2035, driven by rapid digitization penetration and increased downtime causing production loss.

Segment Insights:

- The energy and utilities segment in the predictive maintenance market is expected to achieve the largest share by 2035, driven by the need to minimize productivity loss and maintenance costs.

- The solutions segment in the predictive maintenance market is expected to capture a significant share by 2035, attributed to the rising demand for integrated predictive maintenance systems.

Key Growth Trends:

- Rising Demand for Emerging Technologies

- Need to Reduce Maintenance Costs and Downtime

Major Challenges:

- Rising Demand for Emerging Technologies

- Need to Reduce Maintenance Costs and Downtime

Key Players: C3.ai. Inc., Software AG, PTC, Asystom, Uptake Technologies Inc., TIBCO Software Inc., Wavelabs, OMRON Corporation, SIGMA Industrial Precision, DINGO Software Pty. Ltd., Operational excellence group limited (OPEX) Group Ltd., Fiix Inc., Ecolibirium Inc., Softweb Solutions Inc., S A S Institute Inc., Schneider Electric, General Electric, SAP SE, Microsoft Corporation, IBM Corporation, Siemens AG, Hitachi Consulting Corporation, Fujitsu Limited.

Global Predictive Maintenance Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 14.31 billion

- 2026 Market Size: USD 18.24 billion

- Projected Market Size: USD 205 billion by 2035

- Growth Forecasts: 30.5% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (29% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: United States, Germany, China, Japan, United Kingdom

- Emerging Countries: China, India, South Korea, Brazil, Mexico

Last updated on : 10 September, 2025

Predictive Maintenance Market Growth Drivers and Challenges:

Growth Drivers

- Rising Demand for Emerging Technologies - The rising adoption of technology for running the business efficiently is likely to increase the popularity of predictive maintenance technology. Around 65% of companies are looking forward to switching to various technologies and over 77%, who have already implemented the technology have expressed above-average satisfaction with it.

- Need to Reduce Maintenance Costs and Downtime - Predictive maintenance market predicts the time of equipment failure and prevents its further failure, thus reducing the downtime and maintenance cost of the company. For industrial businesses, downtime often costs between USD 30,000 and USD 50,000 per hour. This indicates that downtime can reasonably cost the average business between USD 10 and USD 25 million a year.

- Growing Adoption of IoT (Internet of Things) by the Company - Integration of IoT in predictive maintenance enables businesses to identify potential safety hazards, take action, and estimate problems before they have an impact on employees. In the next two years, starting from 2021, around 80% of businesses want to spend a considerable amount of money on at least one IoT project.

- Massive Generation of Data - Predictive maintenance uses the data-driven technique by using real-time data for finding any sort of anomalies in machines. Global data production, collection, transfer, and usage are all expected to rise sharply, reaching 64.2 zettabytes in 2020. Global data generation is anticipated to increase to more than 180 zettabytes over the following five years, up until 2025.

- Increased Prevalence of Digitization Among the Company - Digital transformation is expected to boost predictive maintenance market, by enhancing precision and blowing off downtime dramatically. Around 90% of all businesses have already embraced a digital-first company strategy or have plans to do so, while 55% of startups have done so.

Challenges

- Shortage of Expert Workers in the Market

- Constant maintenance and Upgradation of the System

- Escalating Challenges with Data Privacy - A significant amount of production and manufacturing data is gathered, transferred to, and stored in a database when using a predictive maintenance method. Moreover, the upgradation of industries to industry 4.0 generated a huge amount of data every hour. These industries are at higher risk of cyber-attacks, network breaches, and data theft. Therefore, the use of predictive maintenance can also lead to danger to the huge amounts of data, which in turn develops hesitancy among end users to adopt predictive maintenance.

Predictive Maintenance Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

30.5% |

|

Base Year Market Size (2025) |

USD 14.31 billion |

|

Forecast Year Market Size (2035) |

USD 205 billion |

|

Regional Scope |

|

Predictive Maintenance Market Segmentation:

End-user

The energy and utilities segment is estimated to gain the largest predictive maintenance market size by the end of 2035. The growth of the segment can be attributed to the increasing need for minimizing productivity loss and maintenance costs. Predictive maintenance detects the possible issues in the equipment, which improves its productivity. Unplanned downtime costs the average oil and gas complex 32 hours of lost output each month, or USD 220,000 per hour. At each site, that comes to an annual total of USD 84 million.

Component

The solutions segment is expected to garner a significant market revenue over the forecast period. Furthermore, the solutions segment is categorized into integrated, and standalone. Growing need for a system, that combines all the technologies, to provide more integrated solutions. Such solutions are imperative in vast sectors, such as healthcare, food & beverage, and manufacturing. For instance, higher adoption of electronic medical records in the healthcare sector is expected to create huge demand for predictive maintenance solutions that integrated entire healthcare systems. During the period of the pandemic, nearly 73% of hospitals maintained electronic medical records in Japan. Moreover, in the United States, around 90% of office-based physicians use any one of the electronic health record (HER) systems. Furthermore, the growing need for solutions that have the ability to solve different issues in the industry is also expected to boost the growth of the segment. For instance, supply chain management needs predictive maintenance solutions for better safety & security, integration of the different regions, and most importantly enhances customer experience. On receiving better customer experience, around 89% of customers are believes to come back to the company make another purchase.

Our in-depth analysis of the global market includes the following segments:

|

By Component |

|

|

By Deployment Mode |

|

|

By Organization Size |

|

|

By End User Vertical |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Predictive Maintenance Market Regional Analysis:

APAC Market Insights

The Asia Pacific predictive maintenance market, amongst the market in all the other regions, is poised to dominate 29% revenue share by 2035. The growth of the market can be attributed majorly to the rapid penetration of digitization in the company. Around 70% of major corporations and middle-market businesses in the APAC region have a digital transformation strategy in place, with Taiwan leading the pack with 95%. This represents an increase from 2020 when 57% of APAC businesses had a digital strategy. Furthermore, the rise in the downtime occurring in the industry, which in turn leads to production loss is also expected to boost the market growth. Disruption in the supply chain management had increased the average downtime days by approximately 95% in the energy industries of the Asia Pacific region.

Predictive Maintenance Market Players:

- C3.ai. Inc.

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Software AG

- PTC

- Asystom

- Uptake Technologies Inc.

- TIBCO Software Inc.

- Wavelabs

- OMRON Corporation

- SIGMA Industrial Precision

- DINGO Software Pty. Ltd.

- Operational excellence group limited (OPEX) Group Ltd.

- Fiix Inc.

- Ecolibirium Inc.

- Softweb Solutions Inc.

- S A S Institute Inc.

- Schneider Electric

- General Electric

- SAP SE

- Microsoft Corporation

- IBM Corporation

- Siemens AG

- Hitachi Consulting Corporation

- Fujitsu Limited

Recent Developments

-

Software AG launched ARIS, a new toolkit that assists the planning, execution, and evaluation of sustainability activities. This free solution centers processes around its clients' sustainability plans, aiding in their execution and making them transparent and verifiable.

-

Asystom announced its selection for the predictive maintenance project implemented by Northumbrian Water Limited. The organization aims at implementing predictive maintenance in order to prevent breakdowns, offer their customers with uninterrupted services, and lower operating costs.

- Report ID: 4675

- Published Date: Sep 10, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Predictive Maintenance Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.