Die Casting Machines Market Outlook:

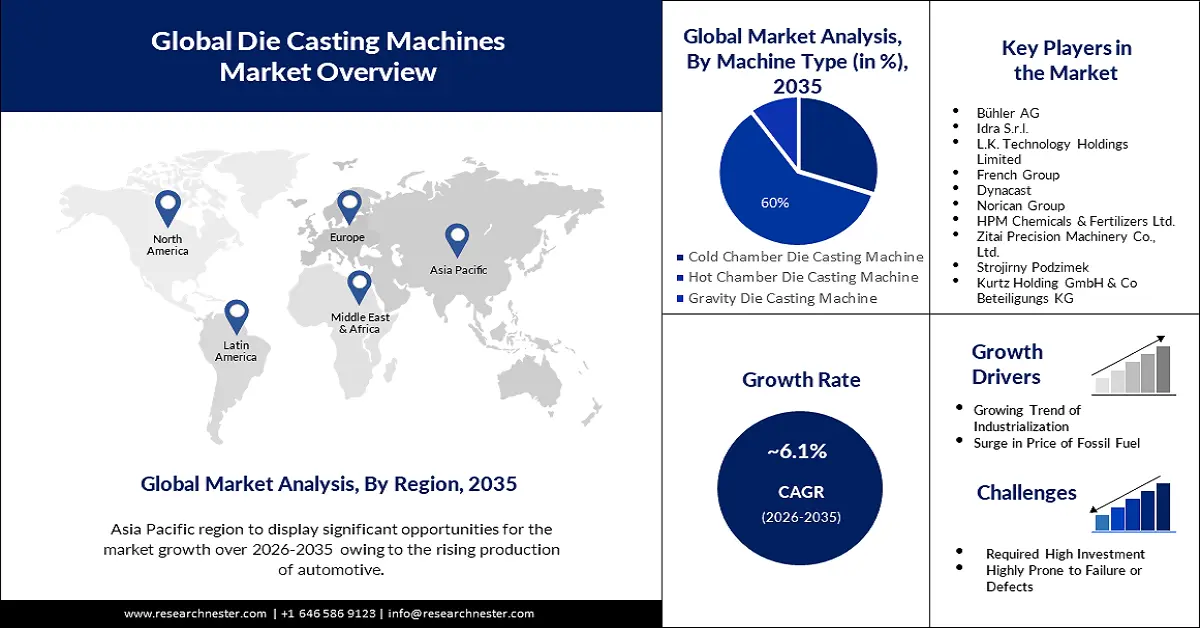

Die Casting Machines Market size was valued at USD 3.57 Billion in 2025 and is expected to reach USD 6.45 Billion by 2035, registering around 6.1% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of die casting machines is evaluated at USD 3.77 Billion.

This growth of the market is projected to be dominated by growing demand for lightweight vehicles. For instance, the United States automotive industry sold over 12 million light vehicle units in 2022. Approximately 3 million passenger automobiles and about 9 million light trucks were sold at retail. As a result, the demand for die casting machines is also surging.

The automotive industry is characterized by fierce rivalry, which is fueled by the need to lower emissions and increase fuel efficiency. Given the unprecedented number of vehicles on the road, it is now essential to reduce weight in order to save fuel and cut CO2 emissions. Die casting is a solution that manufacturers have discovered to satisfy the demands of the automotive sector. Hence, the market revenue for die-casting machines is estimated to rise.

Key Die Casting Machines Market Insights Summary:

Regional Highlights:

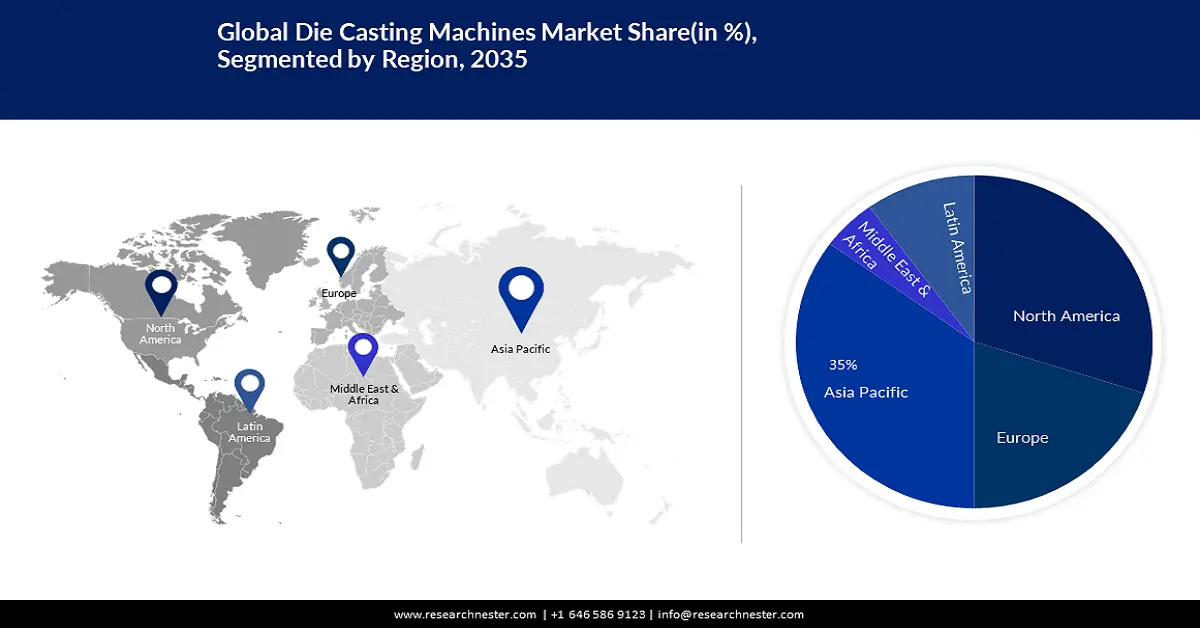

- Asia Pacific die casting machines market is projected to capture a 35% share by 2035, driven by rising production of automobiles.

Segment Insights:

- The hot chamber die casting machine segment in the die casting machines market is expected to see significant growth through 2035, driven by benefits like faster cycle times, intricate details, and longer machine life.

- The aluminum segment in the die casting machines market is expected to experience substantial growth over 2026-2035, driven by increasing use in electric vehicles due to aluminum's lightweight and conductivity.

Key Growth Trends:

- Growing Trend of Industrialization

- Surge in Price of Fossil Fuel

Major Challenges:

- Required High Investment

- Highly Prone to Failure or Defects

Key Players: Bühler AG, Oskar Frech GmbH + Co. KG, Toshiba Machine Co., Ltd., UBE Machinery Corporation, Ltd., Italpresse Gauss (Norican Group), Dynacast International, L.K. Machinery International Limited, Idra S.r.l., Toyo Machinery & Metal Co., Ltd., Shibaura Seiki Co., Ltd.

Global Die Casting Machines Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 3.57 Billion

- 2026 Market Size: USD 3.77 Billion

- Projected Market Size: USD 6.45 Billion by 2035

- Growth Forecasts: 6.1% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (35% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: China, United States, Germany, Japan, India

- Emerging Countries: China, India, Thailand, Vietnam, Indonesia

Last updated on : 11 September, 2025

Die Casting Machines Market Growth Drivers and Challenges:

Growth Drivers

-

Growing Trend of Industrialization- There has been a surge in industrialization all across the globe. A number of things, such as governmental regulations, labor-saving technologies, aspirations of entrepreneurs, and consumer demand are all major elements to boost industrialization. Further, the global trend of industrialization is also increasing demand for industrial equipment employed to create a variety of alloy parts in various forms and sizes. As a consequence, it has become one of the main drivers driving the die casting machine market. With advantages including excellent tolerance power, minimal porosity, textured and smooth surfaces, exact repeatability, and precisely defined parts, die casting machines are also utilized to produce large castings quickly. Hence, with the consumer preference could be satisfied.

- Surge in Price of Fossil Fuel- Subsidies for the use of fossil fuels increased dramatically globally in 2022, surpassing about USD 2 trillion for the first time. The need for fossil fuels increased as nations attempted to emerge from the economic slump brought on by the COVID-19 epidemic at the end of 2021, pushing up the price of crude oil and gasoline as people sought an uninterrupted supply. Furthermore, sanctions against Russian-produced fossil fuels have resulted from the conflict in Ukraine, which was sparked by one of the gas and oil suppliers. Countries are now scurrying to find supplies elsewhere, especially from nations with highly subpar human rights records including Saudi Arabia and the United Arab Emirates. However, all these factors greatly affect the sale of automobiles which is why more emphasis is now given on light duty vehicles.

- Rise in Advancement in Die Casting- The industrial industry is changing owing to these cutting-edge technologies. Businesses can benefit from these advantages, which include more output, lower costs, and better-quality products. From melting the metal to cooling the mold, IoT technology can track and report on every stage of the die-casting process. To collect data on variables including pressure, temperature, and humidity, Internet of Things (IoT) sensors may be placed at various points during the process. Therefore, the market is poised to observe great growth in its revenue over the coming years.

Challenges

-

Required High Investment - Die casting has demonstrated to be a very successful and economical method of making components in large quantities. However, it's an undeniable reality that the initial cost (when the castings are made and the process starts) may be significant.

- This early investment requirement may discourage start-ups and smaller enterprises. Therefore, the market revenue is projected to be restrained.

- Highly Prone to Failure or Defects - Die cast parts are renowned for their precise detail and accuracy when executed correctly and thoughtfully designed, yet things may go wrong. Inadequate coverage of all the early phases might result in misruns, cold shuts, and porosity problems. Merely one of the many reasons why it's crucial to collaborate with a trustworthy and knowledgeable die casting provider. However, this may create a lack of trust for small businesses which would make them consider the alternative options. As a result, the market for this might be hindered.

- Requires Only Use of Non-Ferrous Metals

Die Casting Machines Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

6.1% |

|

Base Year Market Size (2025) |

USD 3.57 Billion |

|

Forecast Year Market Size (2035) |

USD 6.45 Billion |

|

Regional Scope |

|

Die Casting Machines Market Segmentation:

Raw Material Segment Analysis

The aluminum segment in the die casting machines market is projected to capture the highest share of about 55% by 2035. Automobile manufacturers are increasingly using die casting machinery for manufacturing aluminum components and parts instead of iron and steel since it is significantly lighter than steel and has several additional benefits, such as ductility over other materials. In the market for raw materials, aluminum has a strong advantage. Additionally, with the growing demand for electric vehicle this segment is also set to experience growth since this material offers great conductivity to the EV. 2022 started off strong, shattering previous records. Sales of electric vehicles (EVs) surpassed approximately 9 million, accounting for about 13% of all new automobiles sold. This represents a significant increase from over 8% in 2021.

Machine Type Segment Analysis

Die casting machines market from the hot chamber die casting segment is projected to generate the highest share of over 60% during the forecast period. This is due to benefits such as faster-cycling manufacturing, intricate cast-in detail, decreased porosity, and longer die-casting life due to lower melting points and die design efficiencies. Both zinc and magnesium are produced using the hot chamber die casting technique. These materials are considered to be the best option for electronic items such as medical devices which further include X-ray machines, and more.

Our in-depth analysis of the global die casting machines market includes the following segments:

|

Machine Type |

|

|

End-User |

|

|

Raw Material |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Die Casting Machines Market Regional Analysis:

APAC Market Insights

The Asia Pacific die casting machines market is set to hold 35% of the revenue share by 2035. The major factor to drive the market expansion in this region is the rising production of automobiles. For instance, China's passenger automobile sector produced over 22 million vehicles in 2022. In Asia Pacific, possessing an automobile may be a source of pride for a tiny minority of people, however, the majority are more interested in the car's practicality. Hence, the utilization of die casting machines is growing in this region to manufacture automobiles. Additionally, there has been a surge in investment in manufacturing activities which is additionally surging the employment of die casting machines.

North American Market Insights

The die casting machines market in North America is expected to have significant growth during the forecast period. The growth of the market in this region is set to rise on account of growing technology advancement in this region. Moreover, this region invests heavily in advancing the die casting machines which is why the adoption of this machine is rising. The integration of cutting-edge technologies, which include automation, robotics, and digital control systems, has proven advantageous for die casting machines in this region. With the goal of satisfying the increasing needs of contemporary manufacturing, these developments have enhanced production speed, precision, and overall operational efficiency. Hence, the market expansion in this region is experience growth over the coming years.

Die Casting Machines Market Players:

- Bühler AG

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Idra S.r.l.

- L.K. Technology Holdings Limited

- French Group

- Dynacast

- Norican Group

- HPM Chemicals & Fertilizers Ltd.

- Zitai Precision Machinery Co., Ltd.

- Strojirny Podzimek

- Kurtz Holding GmbH & Co Beteiligungs KG

Recent Developments

- Bühler AG has expanded its product line with the Carat 840 and the Carat 920 in response to the growing demand in the automobile industry for larger and more intricate parts. Because Bühler's die-casting platforms are produced in North America, Europe, and Asia, quick delivery times are guaranteed due to convenient transportation routes and a consistent supply of spare parts. Clients may count on a reliable worldwide manufacturing network. Local service engineers provide prompt on-site help, remote support, and comprehensive on-site or application centre training to foundries and automobile manufacturers.

- The installation of an ItalPresseGauss TF5700 High Pressure Die Casting (HPDC) machine is the latest project that Nantong Jiangzhong Photoelectricity Co., Ltd. has officially inaugurated. The project launch ceremony, which takes place on February 1, 2021, at the company's base in Jiangsu Province, China, is in accordance with the agreement that was reached at the end of 2020.

- Report ID: 5371

- Published Date: Sep 11, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Die Casting Machines Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.