Precision Gearbox Market Outlook:

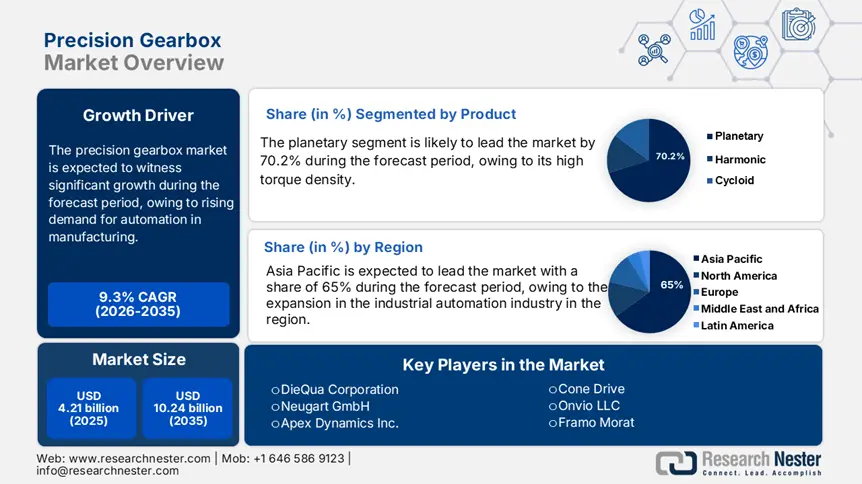

Precision Gearbox Market size was valued at USD 4.21 billion in 2025 and is likely to cross USD 10.24 billion by 2035, expanding at more than 9.3% CAGR during the forecast period i.e., between 2026-2035. In the year 2026, the industry size of precision gearbox is assessed at USD 4.56 billion.

The global transition to electric vehicles and renewable energy systems, especially wind power, is fueling the adoption of precision gearboxes. The performance, along with the driving experience in electric vehicles, depends heavily on precision gearboxes that ensure efficient power transmission and noise reduction. Wind turbines are needing gearboxes that boost the speed from low-speed rotors to match higher-speed generator requirements for optimized energy output.

New advancements in wind turbine gearboxes are improving energy efficiency and reliability, extending the reliability of wind energy production and equipment operation times. The increasing focus on renewable energy creation is also attracting new investments into wind energy initiatives, which stem from public sector support measures and private business participation. For instance, in November 2023, the Odisha government gained wind energy project investments totaling USD 60 million in new capital from potential investors. Multiple investors presented a USD 60 million suggestion to the management and senior government officials, as well as officials from the GRIDCO state nodal agency for a wind energy project of 575 MW capacity.

Key Precision Gearbox Market Insights Summary:

Regional Highlights:

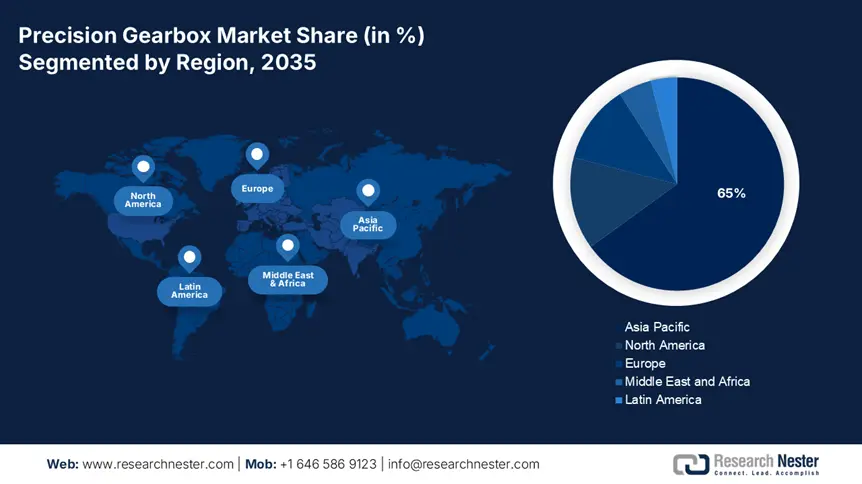

- Asia Pacific commands a 65% share in the Precision Gearbox Market, driven by rapid industrial automation and rising investment in advanced manufacturing, ensuring strong growth through 2035.

- North America's Precision Gearbox Market is forecasted for significant growth by 2035, fueled by growing use of cobots and medical robotics in precision applications.

Segment Insights:

- The Robotics segment is expected to see steady growth through 2026-2035, driven by the increasing demand for automated systems requiring precision gearboxes to enhance efficiency and performance.

- The planetary gearbox segment is projected to achieve a 70.2% share by 2035, driven by its high torque density and compact size, ideal for robotics and aerospace applications.

Key Growth Trends:

- Rising demand for automation in manufacturing

- Advancements in material technology

Major Challenges:

- Increasing adoption of direct drive systems

- Limited compatibility with high-speed applications

- Key Players: NIDEC-SHIMPO CORPORATION, Harmonic Drive LLC, Stöber Antriebstechnik GmbH and Co. KG, DieQua Corporation, and Neugart GmbH.

Global Precision Gearbox Market Forecast and Regional Outlook:

Market Size & Growth Projections:

- 2025 Market Size: USD 4.21 billion

- 2026 Market Size: USD 4.56 billion

- Projected Market Size: USD 10.24 billion by 2035

- Growth Forecasts: 9.3% CAGR (2026-2035)

Key Regional Dynamics:

- Largest Region: Asia Pacific (65% Share by 2035)

- Fastest Growing Region: Asia Pacific

- Dominating Countries: China, Germany, Japan, United States, Italy

- Emerging Countries: China, India, Japan, South Korea, Thailand

Last updated on : 12 August, 2025

Precision Gearbox Market Growth Drivers and Challenges:

Growth Drivers

- Rising demand for automation in manufacturing: Various manufacturing sectors, including robotics, aerospace, and automotive, are implementing automation, creating a surging demand for precision gearboxes. Automated systems depend on precise torque transmission through high-end precision gearboxes to prevent backlash emergence at a level to maintain operations. For instance, in February 2022, Nabtesco revealed its manufacturing investment plans to enhance its precision gearbox output to two million units yearly by 2026 by establishing a new manufacturing facility.

- Advancements in material technology: Recent advances in material technology combined with 3D printing result in substantial improvements for the precision gearbox industry. The implementation of 3D printing technology into precision gearbox manufacturing is enabling price reduction and design enhancement capabilities for the industry. Companies are developing cold spray technology for rapid metal component production, which results in making vital parts in under a few minutes. In October 2023, the Ukranian Armed Forces adopted SPEE3D's technology to create replacement components for military equipment, which probed the effectiveness of handling present shortages and operation delays. The advancement highlights the potential of 3D printing technologies to optimize industrial processes for prompt originator creation and immediate production of precision gearbox components to fulfill changing precision gearbox market requirements.

Challenges

- Increasing adoption of direct drive systems: Direct drive systems remove mechanical gears from systems, which reduces energy losses and operating expenses as well as produces improved operational performance. Meanwhile, magnetic gear technology implements power through contactless transmission platforms, improving durability and reducing wear. The rise of alternative solutions in robotics, wind energy, and industrial automation is restricting the growth of conventional precision gearbox solutions.

- Limited compatibility with high-speed applications: Precision gearboxes struggle with high-speed applications due to friction-induced heat generation and wear. Increased mechanical stress during elevated speeds results in reduced efficiency, degraded performance, and increased maintenance requirements of the system. The aerospace and automotive fields, together with high-speed robotics industries, are looking for alternative drive solutions that include direct drive motors to benefit from enhanced performance and diminished heat generation. The broad implementation of precision gearboxes at ultra-high speeds remains restricted, as these components are experiencing limited compatibility with such applications.

Precision Gearbox Market Size and Forecast:

| Report Attribute | Details |

|---|---|

|

Base Year |

2025 |

|

Forecast Period |

2026-2035 |

|

CAGR |

9.3% |

|

Base Year Market Size (2025) |

USD 4.21 billion |

|

Forecast Year Market Size (2035) |

USD 10.24 billion |

|

Regional Scope |

|

Precision Gearbox Market Segmentation:

By Product (Planetary, Harmonic, Cycloid)

Planetary segment is anticipated to account for around 70.2% precision gearbox market share by 2035. The growth is attributed to the high torque density and the small size of planetary gearboxes, which work perfectly for applications needing tight installation spaces. Industries such as robotics and aerospace benefit from planetary gearboxes due to their high efficiency and load distribution capabilities. In June 2023, Schaeffler showcased its premium high-precision planetary gearboxes and their vital role in industrial robotic systems at Automatica 2023.

Application (Robotics, Medical, Packaging, Food, Beverage, and Tobacco, Military and Aerospace, Materials Handling, Machine Tools)

The robotics segment in precision gearbox market is expected to witness a steady growth due to the increasing demand for automated systems from various sectors. Machine automation is accelerating the robotic precision gearbox requirements, which is leading to better efficiency as well as enhanced accuracy. Technological innovations are fueling the segmental growth, boosting the performance capabilities and versatility of the robotics precision gearbox. The enhancement of gear design using optimized shapes and tooth profiles also creates improved efficiency and reliability, expanding their popularity in high-precision applications.

Our in-depth analysis of the global market includes the following segments:

|

Product |

|

|

Type |

|

|

Application |

|

Vishnu Nair

Head - Global Business DevelopmentCustomize this report to your requirements — connect with our consultant for personalized insights and options.

Precision Gearbox Market Regional Analysis:

Asia Pacific Market Analysis

Asia Pacific in precision gearbox market is expected to hold over 65% revenue share by the end of 2035. This growth is attributed to accelerating expansion within the industrial automation sector. The countries, including China and Japan, are deploying substantial resources to purchase advanced manufacturing equipment as well as robotics and CNC machinery to achieve higher production performance.

The precision gearbox market is growing, attributed to industries adopting smart manufacturing, which requires more efficient and durable gear systems with precision performance. The rapid increase of electric vehicle production throughout the region is also driving the demand for precision gearboxes in the region, which are installed in drivetrains coupled with energy-efficient power transmission systems. The increasing focus on better performance and reduced energy use by manufacturers is fostering market growth due to the government's adoption of strict emission requirements and EV adoption incentives.

The China precision gearbox market is experiencing steady growth, owing to the investments in highly accurate manufacturing technologies focused on semiconductor production, aerospace applications, and medical devices development. The country is strengthening its industrial output capacity to meet growing needs for high-accuracy motion control precision gearboxes. The focus on reducing manufacturing process cycle times and creating miniaturized products is also driving the manufacturers to adopt advanced precision gearbox solutions.

The precision gearbox market in India is highlighting a steady expansion, attributed to the rapid expansion of the country’s renewable energy sector. The growth of wind turbine installations throughout India is rising as the country is pursuing renewable energy targets that demand precision gearboxes for optimal power transmission and product longevity. The adoption of superior gearbox technologies is aimed at improving turbine reliability and performance due to the government support for clean power and funding investments made by domestic and international companies in wind farms.

North America Market

The precision gearbox market in North America is expected to witness a significant expansion during the forecast period, as companies in the region are leveraging collaborative robots. The addition of cobotic systems into operations that demand accuracy, such as microelectronic assembly and medicine production, is creating a rising demand for sophisticated motion control systems. The demand for precision gearboxes is also increasing with the rising installations of robotic-assisted surgeries and high-precision medical devices across the region. There has been a rise in the adoption of medical robots in the region’s healthcare sector to achieve better movement accuracy and reliability in their operations. Parameters in robotic-assisted technologies for minimally invasive healthcare procedures are receiving heightened production interest in the region for specialized precision gear solutions for medical requirements.

The precision gearbox market in the U.S. is anticipated to increase at a fast pace due to the continually rising agriculture sector's automation to build autonomous tractors, robotic harvesters, and smart irrigation systems. Precise gear technology is enhancing the farming equipment's efficiency and durability by providing better motion control systems, which boosts productivity levels. Manufacturers are integrating precision gear solutions to improve agricultural automation due to labor shortages and sustainable farming needs, thus driving market expansion.

The precision gearbox market in Canada is witnessing steady growth, owing to the development of renewable energy using wind power and hydroelectric energy. The government's goal for carbon emissions reduction, along with its 2050 net-zero target, is resulting in growing wind farm and hydroelectric construction, which drives precision gearbox adoption. In October 2024, the government pursued USD 1.6 billion of renewable energy investments through projects that need advanced gearboxes to optimize power generation in Alberta and Ontario. The precision gearbox market in the country for electric and hybrid mining equipment requires precise motion control systems that drive the need for innovative gearbox solutions.

Key Precision Gearbox Market Players:

- Stöber Antriebstechnik GmbH and Co. KG

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- DieQua Corporation

- Neugart GmbH

- WITTENSTEIN SE

- GAM ENTERPRISES, INC.

- Apex Dynamics, Inc.

- Hiwin Corporation

- Wilhelm Vogel GmbH

- Cone Drive

- Sureservo

- SEW-EURODRIVE GmbH & Co KG

- ATLANTA Drive Systems, Inc.

- Framo Morat

- Onvio LLC

- PARKER HANNIFIN CORP

- Güdel Group AG

- EGT Eppinger Getriebe Technologie GmbH

- ABB Motors and Mechanical Inc.

- SWG Solutions

- Bonfiglioli Riduttori S.p.A.

- Ondrives Ltd.

- Designatronics Inc.

- GEORGII KOBOLD GmbH & Co. KG

- igus GmbH

- Genesis Robotics

- Motus Labs

The competitive landscape of the precision gearbox market is rapidly evolving, attributed to the integration of advanced technologies in the industry by key players. They are focused on developing new technologies catering to various industries, following the stringent regulatory norms and consumer demand. These key players are adopting several strategies, such as mergers and acquisitions, joint ventures, partnerships, and novel product launches, to enhance their product base and strengthen their market position. Here are some key players operating in the global precision gearbox market:

Recent Developments

- In October 2024, Neugart introduced three new precision planetary gearboxes, expanding its precision line portfolio with a compact 55 mm frame size. These gearboxes offer high torque density and precision, making them ideal for electronically controlled servo drives in packaging and automation industries.

- In September 2023, Schaeffler announced the launch of the precision strain wave gear series RT1 and RT2, along with precision planetary gearboxes PSC, expanding its range of precision gearboxes and bearings.

- Report ID: 7352

- Published Date: Aug 12, 2025

- Report Format: PDF, PPT

- Explore a preview of key market trends and insights

- Review sample data tables and segment breakdowns

- Experience the quality of our visual data representations

- Evaluate our report structure and research methodology

- Get a glimpse of competitive landscape analysis

- Understand how regional forecasts are presented

- Assess the depth of company profiling and benchmarking

- Preview how actionable insights can support your strategy

Explore real data and analysis

Frequently Asked Questions (FAQ)

Precision Gearbox Market Report Scope

Free Sample includes current and historical market size, growth trends, regional charts & tables, company profiles, segment-wise forecasts, and more.

Connect with our Expert

Copyright @ 2026 Research Nester. All Rights Reserved.