Automotive Interior Plastic Component Market Overview

Plastic is one such material that has extensive properties covering scratch resistant, thermal stability to high volume and weight resistant. All these properties in combination are hugely beneficial to the automotive industry. Apart from the faster manufacturing time for a car to increasing fuel efficiency of the engine can be achieved by using plastic component. Plastic materials also help in innovation of the appearance of the car. Other than improving the functionality, appearance, and safety of automobiles, it helps the companies in delivering superior value to the consumers. New and upgraded automotive components that were earlier available only in premium class car are now available in mid-range passenger cars too due to extensive use of plastic components thus contributing additionally in the automotive interior plastic component market progression.

Market Size & Forecast

The automotive interior plastic component market is estimated to expand at a CAGR of around 11% over the forecast period i.e. 2019-2027. Advancements in the plastic industry in the past few years and growing research and design activities in automotive sector are projected to drive the automotive interior plastic component market during the forecast period.

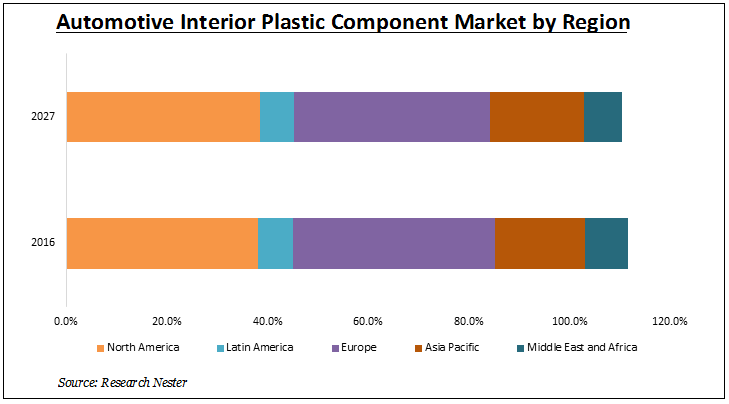

On the basis of regional platform, global automotive interior plastic component market is segmented into five major regions including North America, Europe, Asia Pacific, Latin America and Middle East & Africa region.

Europe is likely to dominate the global automotive interior plastic components market owing to high consumer demand for passenger vehicles. European automobile manufacturers are using high-performance plastics as these materials help in fuel efficiency by reducing the weight of vehicles. Stringent emission standards have forced the automakers in European region to shift from diesel engines to electrified motors. This is also expected to augment the product demand over the next few years. North America is expected to stand at second position in the automotive interior plastic components market owing to the demand for premium class of automotive. Asia-Pacific is an emerging market in this sector owing to the shift in production bases from developed countries to developing countries. Countries such as India, Indonesia and China are anticipated to positively influence the global automotive interior plastic component market due to cheap labor cost, land cost and other fixed costs.

Get more information on this report: Download Sample PDF

Growth Drivers & Challenges

Growing Demand for Fuel Efficient Vehicle

Rising cost of fuels all over the world is pushing the customers to opt for the vehicles with better fuel efficiency. In order to attract more customers and retain customers, companies are making light weight vehicles to improve upon fuel efficiency. Metals and other heavy weight elements are being replaced by plastic which provides better strength with improved efficiency. Plastic monomers are polymerized using chemical reactions and catalysts to form polymers and co-polymers and are turned into Polypropylene (PP), Polyethylene (PE), Polyvinyl Chloride (PVC), Polystyrene (PS), and other such polymerized materials. These materials possess far better properties than their respective monomers and are extremely stable for use in molding and fabrication. Thus reducing weight offers a cost-effective method to enhance fuel efficiency and this will lead to a sustained level of high growth of automotive interior plastic component market.

Government Regulations to Control Vehicular Emission

Weight reduction offers a cost-effective method of reducing Greenhouse Gas (GHG) emissions and fuel consumption hence helping in conservation of non-renewable crude oil reserves. For example every 1 kg weight decrease can reduce 20 kg of carbon emission. This pressure on companies to comply with government’s regulation has led them to use plastic component. This increasing need for the plastic component is anticipated to drive the growth rate of the market share.

Restraint

High Cost of Plastic Material

High cost of advanced plastic material as compared to aluminum may hinder the global automotive interior plastic component market growth during the forecast period. Availability of substitute materials such as high strength steel and aluminum which are easy to recycle is likely to hamper the growth of the automotive interior plastic component market.

Market Segmentation

Our-in depth analysis of the global automotive interior plastic component market includes the following segments:

By Vehicle Type

- Passenger Vehicle

- Commercial Vehicle

By Product Type

- Polypropylene (PP)

- Polyurethane (PU)

- Polyvinyl Chloride (PVC)

- Acrylonitrile Butadiene Styrene (ABS)

- Poly Carbonates (PC)

- Others

By Sales Type

- OEM

- Aftermarket

By Region

Global automotive interior plastic component market is further classified on the basis of region as follows:

- North America (U.S. & Canada) Market size, Y-O-Y growth & Opportunity Analysis

- Latin America (Brazil, Mexico, Argentina, Rest of Latin America) Market size, Y-O-Y growth & Opportunity Analysis

- Europe (Germany, UK, France, Italy, Spain, BENELUX, NORDIC, Hungary, Poland, Turkey, Russia, Rest of Europe) Market size, Y-O-Y growth & Opportunity Analysis

- Asia-Pacific (China, India, Japan, South Korea, Indonesia, Malaysia, Australia, New Zealand, Rest of Asia Pacific) Market size, Y-O-Y growth & Opportunity Analysis.

- Middle East and Africa (Israel, GCC (Saudi Arabia, UAE, Bahrain, Kuwait, Qatar, Oman), North Africa, South Africa, Rest of Middle East and Africa) Market size, Y-O-Y growth & Opportunity Analysis

Top Featured Companies Dominating The Market

- Braskem SA

- Company Overview

- Business Strategy

- Key Product Offerings

- Financial Performance

- Key Performance Indicators

- Risk Analysis

- Recent Development

- Regional Presence

- SWOT Analysis

- Bayer Group

- BASF SE

- Saudi Basic Industries Corporation (SABIC)

- Smiths Plastics (PTY) LTD

- PLASTIKON INDUSTRIES, INC.

- National Plastics Group

- Grupo Antolin

- MVC Holdings, LLC

- Barkley Plastics Ltd

- Plastic Molding Technology, Inc.

- Productive Plastics, Inc.

- Tata Sons Ltd

- Nifco Inc.